Question 20: What is the industry experience with managing cracked feedstocks to avoid hydrotreater problems such as fouling, and pressure drop?

OHMES (KBC Advanced Technologies, Inc.)

Again, a lot of these comments are in the Answer Book, so I will skip through part of my remarks. People often forget about the refinery slop processing system. Typically, refiners understand where their cracked stock goes; but if it is typically or abnormally routed to the crude tanks or units, one will have cracked stock throughout the refinery, which can cause problems.

Some of the mitigation options can be summarized in four areas. The first is feed logistics. We would say that if you are going to handle this, you need to do as much direct feeding as possible. Again, it is a refinery; so, it is really not practical to be 100%. If you are going to use storage, all of the tank streams will need to be under a nitrogen blanket or a floating roof tank utilized, even if these are virgin streams that will mix with cracked stock. You will obviously need to check your tanks during regular maintenance and cleaning because, again, the primary causes and ingredients of this foulant formation are the olefins, diolefins, the iron scale around it that acts like a catalyst, and the oxygen.

Once that is under control, another option would be chemical treatment. Some people do put in oxygen scavengers; they will work. Others put in different inhibitors to stop the polymerization from forming, particularly on the initial exchangers. Again, there are mixed results in the plants. Some work; others do not. It is probably worth a trial to see if it fixes your situation.

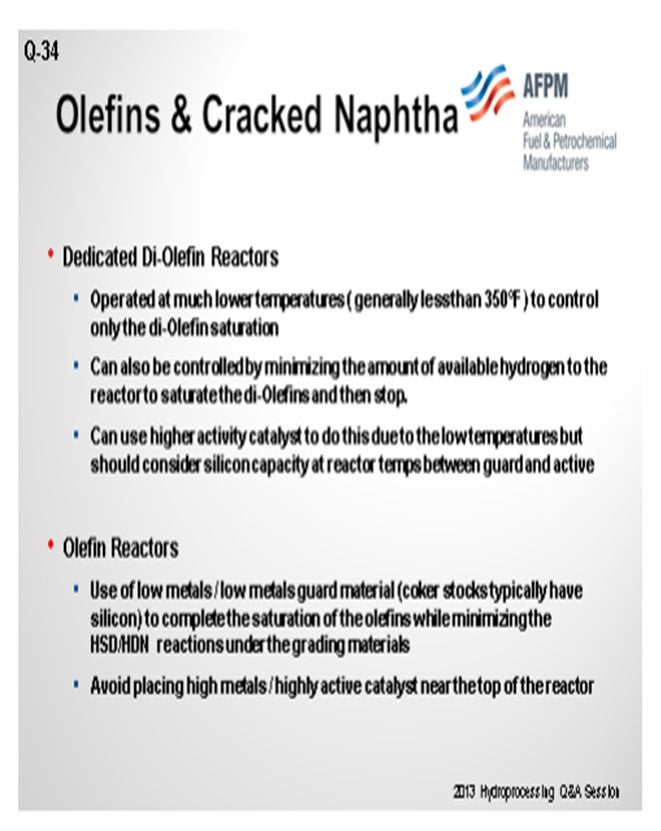

An important area of consideration is the unit configuration. The traditional example is determining how to handle coker naphtha. Some people will have the low temperature diolefin saturation reactor upfront, which can very effective. For those who do not, sometimes putting this coker naphtha in other spots (the response given earlier about putting it in the ULSD or the gas oil unit) is an option. In Asia, many refiners actually put in oxygen strippers to help manage this issue. They will bring in fuel gas, hydrogen, nitrogen, or other media to strip out the tankage feed to remove the oxygen.

The final recommendation concerns the catalyst; and, again, I will defer to the catalyst vendors. There are a lot of different options for catalytically avoiding the polymerization from forming at the top of the reactor. Some refiners include specialized iron trap catalysts which keep that from causing those formations.

LEICHTY (Chevron USA, Inc.)

Chevron has a number of units that store cracked feeds ahead of hydroprocessing units. When doing so, care must be taken to ensure that the tanks are free of oxygen to mitigate unwanted polymerization and gum formation. With the more reactive stocks like coker naphtha, it may be necessary to inject an antioxidant into the rundown and an antifoulant in the hydrotreater feed to mitigate exchanger fouling.

UNIDENTIFIED SPEAKER (Foster Wheeler)

Regarding the storage of cracked products, what is the maximum duration that we can normally store the cracked products? Can we take the cracked products from storage directly back into the hydroprocessing or should they go back to coker or somewhere else?

OHMES (KBC Advanced Technologies, Inc.)

As long as it is under a nitrogen blanket or floating roof, you should be able to store it for quite a while. I do not really have a good rule of thumb on storage time limits, but we have seen refiners go between turnarounds storing cracked stocks. But if you do not have that capability, the cracked products will quickly form polymers. You will then need to either try to rerun the material elsewhere or just take the material, knowing that it will cause problems in the units. Most refiners just get ready for it.

OHMES (KBC Advanced Technologies, Inc.)

Cracked stocks can come from conventional sources, such as coker, FCC, and visbreaker. However, cracked stocks can be found in unexpected streams, such as virgin stream where cracked refinery slop has been introduced to the upstream crude and vacuum unit. The hydroprocessing units most commonly impacted by cracked stock, from a fouling and pressure drop perspective, are the naphtha and diesel hydrotreaters. Some of the typical symptoms of fouling and pressure drop (DP) problems when running cracked stock are:

• Loss of heat recovery in the preheat train, such that the reactor charge furnace has to fire harder,

• Reduced hydraulic capacity, such that flow control valves operates further open or near full-open, and

• High pressure drop across the reactor or first bed, depending on indication points.

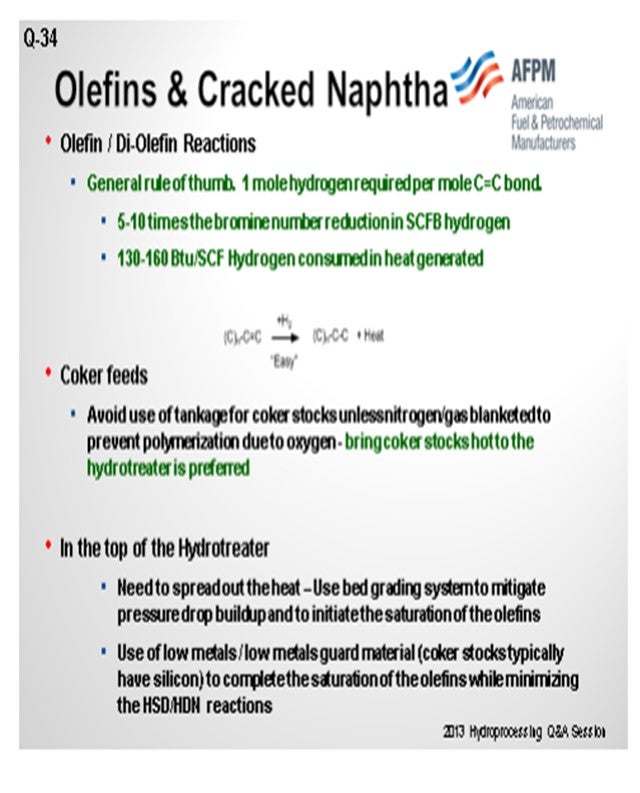

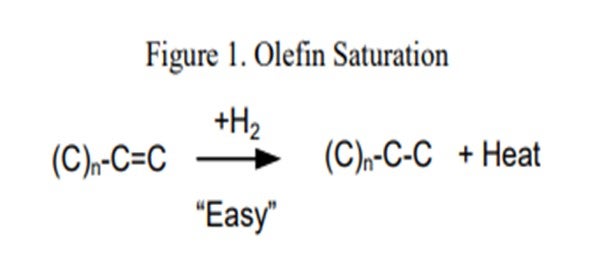

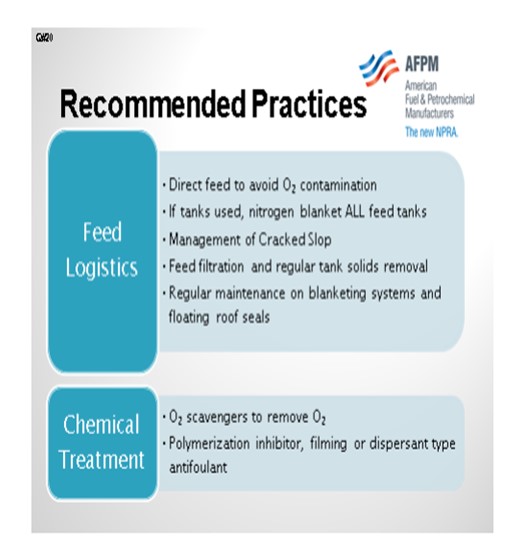

The normal cause of fouling and DP due to cracked stock is polymer formation, which is driven by the olefins and diolefins inherently in cracked streams, oxygen contamination in the feed, and catalyzed by iron contamination. The four management options are feed logistics, chemical treatment, unit configuration, and catalysts.

Feed Logistics

The primary cause of fouling from cracked stocks is O2 contamination. Therefore, all feeds to a hydrotreating unit processing cracked stocks should be sent from the source unit directly to the hydrotreater. If feed from tankage is sent to the hydrotreater, whether that feed is virgin or cracked, the tank should have a nitrogen blanket or should be a floating roof. Regular maintenance on the blanketing systems and floating roof seals are especially important for these services. Using the tanks in a “once-through” mode also assists in minimizing fouling.

As highlighted above, iron can serve as a catalyst to drive polymer formation. Some logistics mitigation options are to use feed filters to remove iron scale and to complete regular tank maintenance to remove corrosion products from streams coming from tankage.

Finally, ensuring that refinery cracked stocks are properly managed and processed is important. Several instances of high fouling have been traced to cracked slop being reprocessed in crude units, thereby “contaminating” virgin streams with cracked material. Normal practice is to segregate virgin and cracked slop and process cracked slop in the coker or send to fuel oil.

Chemical Treatment

Though chemical treatment is an option, the success rate is varied and depends on the severity of the fouling. For oxygen contamination, some refiners have used oxygen scavengers to contain the oxygen contamination. Other refiners have used polymerization inhibitors, filming antifoulants, and dispersant antifoulants to minimize the impact of fouling on the preheat exchangers. For reactors with pressure drop problems, chemicals are available for use to help break up the foulant and provide a temporary reprieve on the pressure drop. For these options, the best option is to discuss with your site chemical vendor to determine options and solicit positive result case studies or contacts.

Unit Configuration

Obviously, one option is to remove the cracked materials from the unit feed, but that option is normally not practical. However, an option may exist to process some or all of selected cracked streams in other hydrotreating units. For instance, some refiners process coker naphtha in the diesel or gas oil hydrotreater, as opposed to processing in a dedicated coker naphtha hydrotreater or mixing in the virgin naphtha hydrotreater, such that the material can be diluted in a larger feed pool.

Processing coker naphtha in conventional naphtha hydrotreating units is possible and common. However, the successful units include a diolefin saturation reactor. This reactor is loaded with low activity catalyst and operated at a relatively low temperature, as the diolefins do not require normal reactor temperature not normal activity catalyst to saturate. This configuration option allows the refiner to saturate the diolefins at low severity, thereby reducing the propensity to form polymers.

From a heat recovery standpoint, several options are available to minimize fouling impacts. First, ensuring some hydrogen is available in each of the preheat exchangers helps reduce polymer formation as the liquid feed is heated to reactor conditions. Most modern designs already have this feature, but older or revamped units can have liquid-only exchangers in the hot circuit that have a tendency to foul. Some licensors and refiners have installed the capability to take exchangers out of service while the unit is in operation to allow online cleaning or have sacrificial exchangers in the preheat train. Avoid using plate heat exchangers, which are prone to fouling. Finally, as a reminder for units which will operate in 100% vapor phase, make sure that the dry point does not occur in the charge furnace, so that deposits are not placed on the furnace tubes.

A final configuration options that some refiners have used is an oxygen stripper on the fresh feed. This option involves installing a low pressure stripper tower that uses hydrogen, natural gas, or fuel gas to strip out any oxygen contamination. However, this configuration option can be capital intensive and requires regular loss of off gas to fuel gas or flare to function properly.

Catalysts

Catalysts have long been the primary reactor pressure drop control mechanism. Most refiners now employ a catalyst grading system on the top bed of the reactor to provide a mechanism to trap contaminants and manage pressure drop escalation during a cycle. Specifically for fouling due to cracked stock, several considerations are suggested:

• In addition to catalyst size grading and progression, also ensure that catalyst activity is being progressed from low to high activity. This approach is similar to the discussions above on diolefin management.

• Special grading material is available that helps better trap and isolate iron scale. Doing so will reduce the tendency for iron catalyzed polymer formation. Discussions with your catalyst vendor about catalytic options should be part of your regular catalyst selection process.

ESTEBAN (Suncor Energy, Inc.)

Hydroprocessing of cracked feedstocks is very common due to the sulfur content of coker and FCC products. These feed streams can often be sent “hot” (directly) to a downstream unit, which prevents potential polymerization reactions due to oxygen ingress at storage tanks. However, storing these materials in feed tanks can result in reactor fouling and pressure drop increase.

Blanketing of tanks that store cracked feedstocks with nitrogen or some other gas is the primary control mechanism to avoid fouling and pressure drop problems resulting from the polymerization of cracked materials when oxygen is present. In some of Suncor’s facilities, cracked feedstocks are stored along with straight run feedstocks in nitrogen-blanketed tanks. In order to ensure proper operation the control instrumentation is inspected and maintained routinely to prevent fouling issues. In our experience, we have identified a malfunctioning N2 blanketing system as a contributing cause to exchanger fouling in a diesel unit. The malfunction had allowed oxygen to enter the tank and react with the cracked material in the tank.

A secondary means of preventing fouling issues is by the use of polymerization inhibitors available from chemical vendors. These are injected into the stream entering the feed tank. Most are approved for use, by licensors and catalyst manufacturers’. However, Suncor does not have experience with these products.

ROGER METZLER (Baker Hughes)

Avoid tankage, if possible. Direct hot rundown to the HDS unit. If intermediate tankage is necessary, nitrogen or fuel gas blanketing should be employed to minimize oxygen intrusion. Treatment with Baker Hughes antioxidants and/or polymerization inhibitors can be effective when the specific polymerization mechanism is identified in order to select the appropriate inhibitor chemistry.