Flatten the curve. Those three words represent life or death for millions of Americans as efforts to stem the spread of the COVID-19 pandemic persist. There is much experts still don’t know about this contagion, but what is known for certain is that beyond social distancing, flattening the curve (represented by the number of COVID-19 cases) is contingent on the availability of personal protective equipment (PPE) and germ-fighting products essential to its containment.

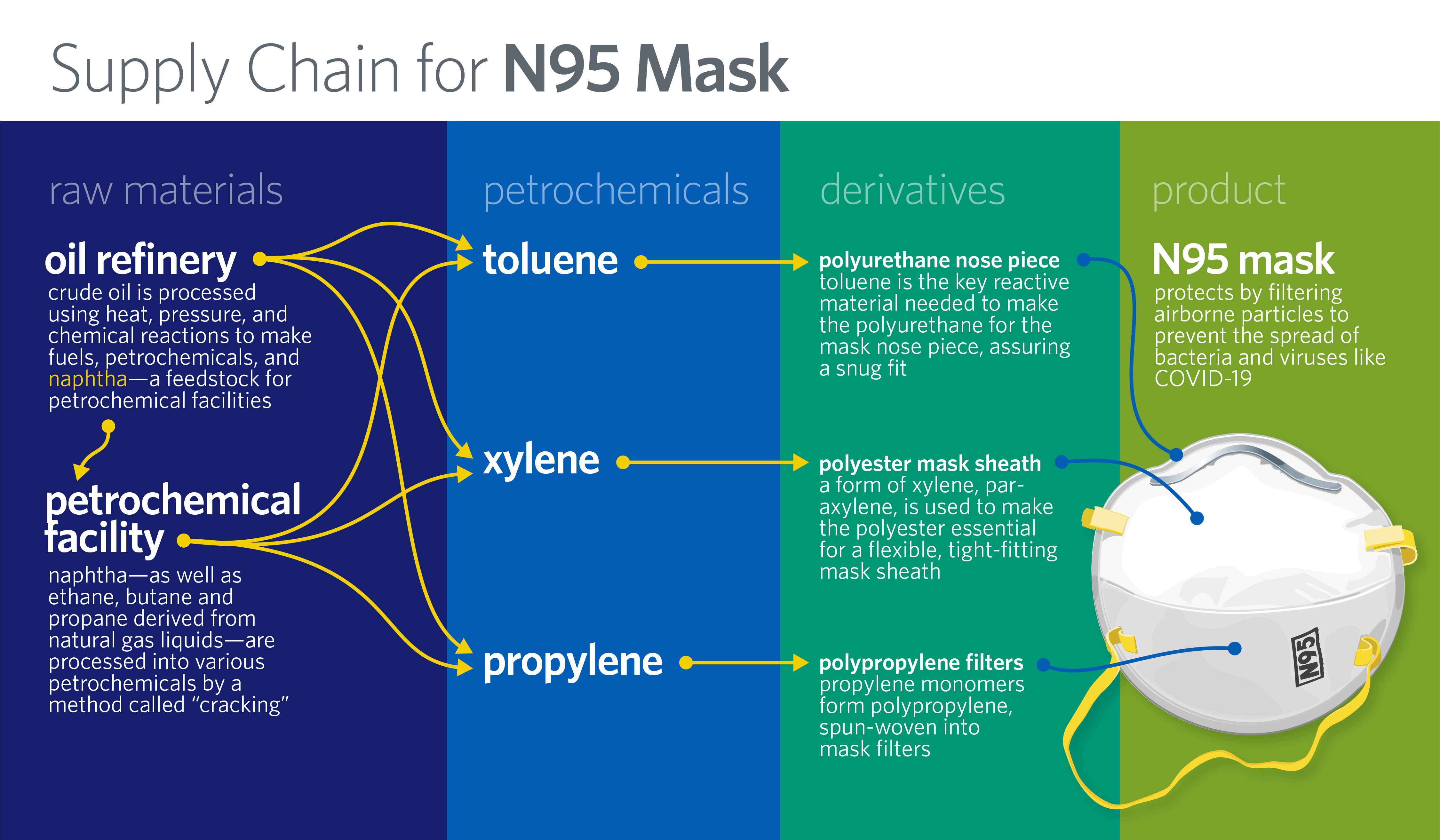

Medical-grade N95 respirator masks that block 95 percent of very small (0.3 micron) particles are critical PPE for health care workers. Demand from medical equipment manufacturers has increased for chemicals integral to PPE and sanitation products, and petrochemical and fuel makers are innovating to keep supply chains moving.

Right now, those critical supplies are depleted due to the scale of the crisis. Designated as critical infrastructure by the Department of Homeland Security, U.S. fuel and petrochemical manufacturers are uniquely suited to maintain supply chains that create everything from hand sanitizer and face masks to protective suits, and the fuels required to transport them. In recent weeks, these industries have proven integral to keeping critical products moving.

“We’re seeing increasing demand for certain petrochemicals from manufacturers of PPE and sanitation products, like polypropylene used to make N95 masks,” said Rob Benedict, senior director, petrochemicals, transportation and infrastructure for the American Fuel & Petrochemical Manufacturers (AFPM). “Our members have been adjusting quickly so they can continue operating safely in spite of the coronavirus and deliver the building-blocks for PPE and other equipment that’s so in need right now.”

The central role of petrochemicals in health care underscores why the U.S. government classifies the petrochemical industry as critical infrastructure. AFPM senior petrochemical advisor Jim Cooper outlines six petrochemicals foundational to hospital settings.

This agility comes from decades of emergency response preparation, which have conditioned petrochemical and fuel manufacturers to safely stay the course through disruptions.

“Robust safety plans and emergency protocols are engrained in these complex operations designed to run 24/7 with hundreds of employees and contractors onsite,” said Chet Thompson, president and CEO of AFPM. “Refiners and petrochemical makers are unwavering on maintaining safe operations. They’ll run facilities safely or not at all.”

Amid the threat of hurricanes and other disruptions in recent years, planning and simulation exercises have enabled fuel and petrochemical manufacturers to quickly establish crisis response management centers, determine minimum employee headcounts needed for safe operations and seamlessly share vital updates with government agencies.

Similar plans were activated across the industries as COVID-19 began to proliferate, and companies are implementing new practices and protocols to safeguard essential workers. Many have a portion of employees working from home, communicating with onsite colleagues increasingly through video technology and smartphone photos. Facilities are stocking up on PPE, enforcing six-foot distancing requirements and adding extra protections like plexiglass screens between operation room stations. Pre-screening surveys and temperature checks—sometimes aided by repurposed infrared scanners to gauge body temperature—are helping worksites limit the spread of the virus.

As essential employees of critical industries work behind the scenes, the coronavirus death toll in the U.S. is rising, ratcheting up pressure to rapidly produce and deliver PPE for frontline workers. How the petrochemical industry is responding is a combination of know-how, collaboration and ingenuity.

The Centers for Disease Control and Prevention (CDC) have determined the virus is most easily contracted by touching one’s nose or mouth after exposure to an infected surface or person—and that makes face shields essential armor for health care workers. As is the case with N95 face masks, only specific materials can guard people from the virus. Eastman Chemical’s glycol-modified polyethylene terephthalate sheet is one of them. The company has partnered with Tennessee’s Higher Education Commission and Austin Peay State University to use these sheets to make 10,000 face shields for medical personnel in Nashville using 3-D printers.

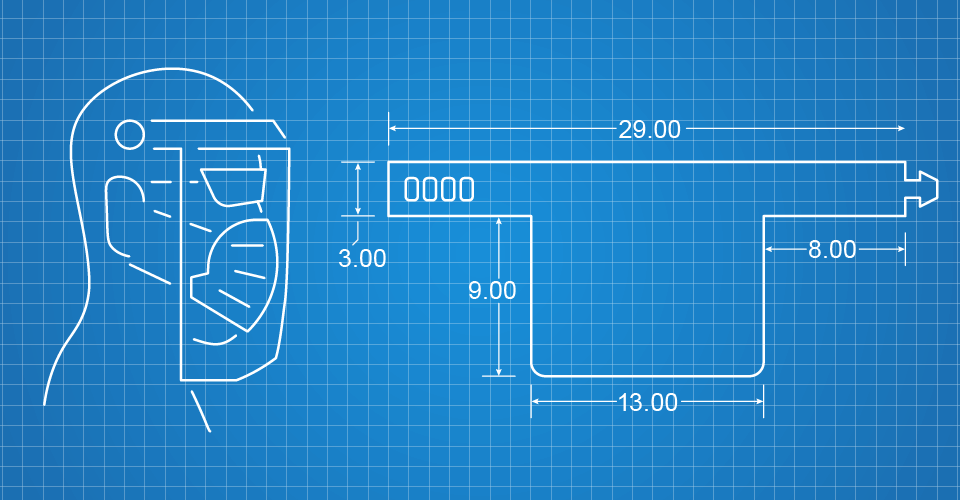

Dow’s simplified design for face shields is comprised of just two pieces—a shield and forehead cushion—streamlining what would typically be a multi-component assembly process.

Dow has also developed a simplified design for face shields to help protect health care professionals and is sharing its design through an open-source file to help accelerate production of this critically needed PPE. Dow is producing 100,000 of these new face shields and donating them to support Michigan hospitals.

ExxonMobil is taking its experience with polymer-based technologies and partnering with the Global Center for Medical Innovation to redesign and manufacture reusable PPE such as face shields and N95 masks. The multi-sector initiative, which is pending approvals from the Food and Drug Administration and the National Institute for Occupational Safety and Health, will facilitate development and third-party production of a PPE gamechanger: safety equipment that can be sterilized and worn multiple times.

Hand sanitizer, once a convenience, is now a necessity in mitigating exposure. When the U.S. marked its first coronavirus death at the end of February, the product saw a 300 percent spike in sales creating an immediate shortage. Many petrochemical and fuel producers took immediate action to respond to this need. Dow employees, for example, are converting five manufacturing facilities across North America, Europe and Latin America to produce hand sanitizer. These facilities do not typically make hand sanitizer, but they are using the raw materials and operational capabilities readily available to enable the new production. Dow estimates their collective facilities will produce more than 880,000 eight-ounce bottles of hand sanitizer to be donated to local health care systems and government agencies.

Companies like Dow are converting their manufacturing sites to meet the overwhelming demand for hand sanitizer, a key weapon against contracting COVID-19. Dow employees in South Charleston, West Virginia, label drums of hand sanitizer in preparation for a donation to local health care systems and government agencies.

The key ingredient in hand sanitizer is isopropyl alcohol (IPA). The CDC recommends products with a 70 percent IPA concentration to inactivate viruses that are genetically related to, and with similar physical properties as, the coronavirus.

LyondellBasell, a major player in the global chemical industry, makes that essential raw ingredient and donated enough of it to Huntsman Corporation to facilitate a five-ton shipment of hand sanitizer for delivery to Huntsman Cancer Institute and the associated medical facilities at the University of Utah.

“Now more than ever, our industry is stepping up to help safeguard our frontline workers,” said Bob Patel, CEO of LyondellBasell. “It is in critical times like these where we have the ability to showcase our resilience, flexibility and commitment to do what we can to help our communities and position them to win the battle against the virus.”

COVID-19 testing kits remain few and far between. Flint Hills Resources (FHR) is producing polypropylene used to make components of the testing kits. Polypropylene is used extensively in the health care industry because of its clarity, low extractables and suitability for the various sterilization methods. Flint Hills Resources medical polypropylene can withstand many sterilization methods such as ethylene oxide, steam and irradiation sterilization that most every-day use plastics cannot.

Petrochemicals are the lynchpin to PPE production, but fuel manufacturers are literally driving the response efforts. While gasoline demand has dropped nearly 50 percent because of the rise in state stay-at-home orders, diesel demand has not seen the same decline, and refineries are shifting to maximize production of this essential fuel to ensure adequate supplies.

“Diesel in particular continues to be relied upon to fuel emergency vehicles, keep tractor trailers that are maintaining supply chains of feedstocks and products on the road, and make all kinds of deliveries possible,” said Susan Grissom, chief industry analyst for AFPM. “Think about field hospitals and transporting all of the parts and equipment for those—we’re really relying on vehicles powered by liquid fuels during this crisis.”

Motiva is one of several refiners helping address the ongoing need for fuel. The company is donating $50,000 worth of gas cards to medical and emergency response organizations in Texas, Maryland and Florida as part of a broader effort by Motiva to strengthen pandemic response and recovery in the communities in which it operates.

Navigating a disaster of this magnitude has no roadmap, but the preparedness plans and incident training experience core to refining and petrochemical operations positioned these facilities well to stay operational and keep supply chains of vital products moving.

“The preparedness, safety culture and dedication of our workforce have enabled our industries to weather unprecedented challenges before, and these same qualities are seeing us through this current crisis,” said AFPM’s Thompson. “We are resilient.”