In the early hours of August 27, Hurricane Laura came ashore as one of the most powerful storms to hit the United States. Even so, many state officials in Texas and Louisiana are crediting planning efforts at the local level that readied resources and got many people out of harm’s way.

The refining industry similarly took measures to prepare in advance of the storm’s impact to protect our facilities, which are considered critical infrastructure. Since Hurricane Laura began to develop, our industries have tracked the storm’s progression and have taken steps to secure our facilities.

The hurricane has temporarily disrupted refinery operations along parts of the Louisiana and Texas Gulf Coast. Of the 3.5 million barrels per day of U.S. refining capacity potentially in its path, our companies slowed or stopped about 2.5 million barrels per day of capacity out of an abundance of caution to ensure the safety of their employees and surrounding communities.

Preventative closures of refineries in advance of a major storm are a central tenet of the refining industry’s storm preparedness protocols. Shutdowns can take several days and are done carefully to ensure the safety of workers and the surrounding community. Following a shutdown, a “ride-out crew” typically remains onsite at the facility to monitor safety and any potential damage resulting from the storm. These preventative measures are effective.

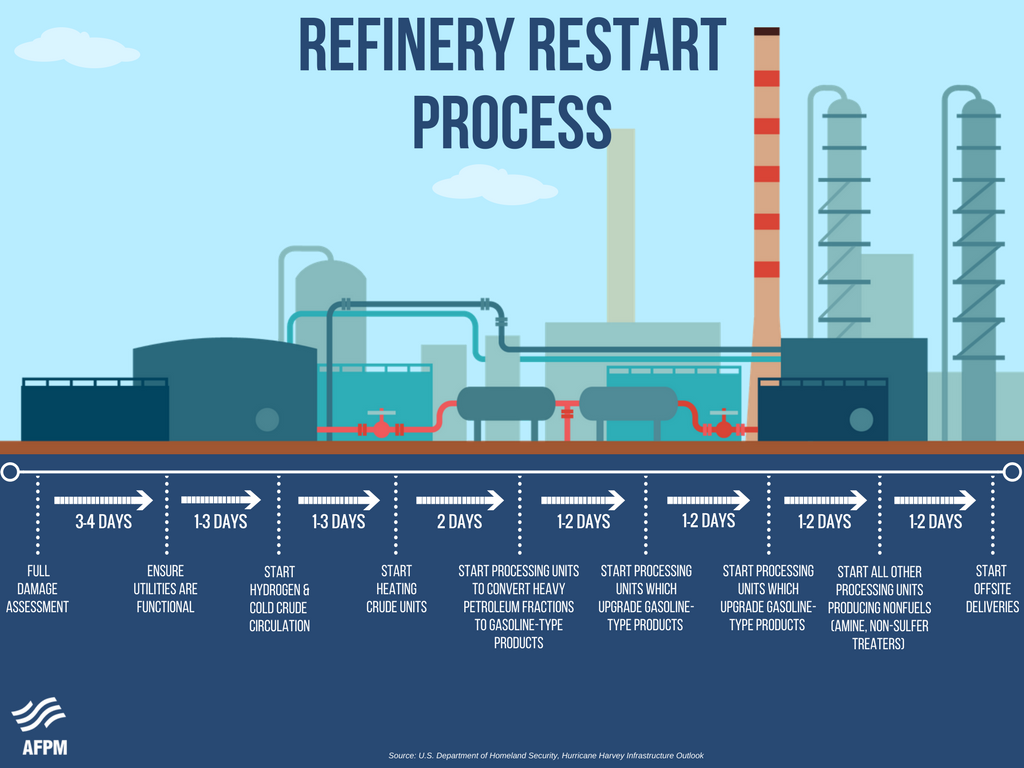

The refineries affected by Hurricane Laura are now conducting damage assessments and developing restart plans. Restarting a refinery is not like flipping a switch and can take as long as two and a half weeks, even when damage from the storm is minimal. The restart process after a storm includes securing safe access to the site and checking the integrity of equipment, storage tanks, process units, and instrumentation. It also includes inspecting facilities for any storm damage, making any necessary repairs, and verifying that there are sufficient feedstocks such as oil and natural gas available from ports and pipelines. Inbound supplies must be able to arrive at the refinery and outbound products must have a clear route to market, so transportation infrastructure is also examined before opening.

When restarting a refinery, operators proceed slowly and carefully because piping systems may have unprocessed hydrocarbons inside of them left over from the shutdown. Operators also work to identify any anomalies or changes in the system as units are brought back online. Making sure each unit is operating normally keeps the overall system safe.

Sometimes refineries must flare during shutdowns or restarts. A flare is first and foremost a safety device, essentially a safety relief valve, which a refinery uses to safely burn excess material, or hydrocarbons, which cannot be recovered or recycled. The excess hydrocarbons are safely burned in the flare, a more environmentally sound method than releasing the hydrocarbons directly into the atmosphere. Flaring is regulated by both the EPA and state environmental agencies and is minimized as much as possible.

Most of the refineries affected by Hurricane Laura are now engaged in the restart process and expect to return to normal operations shortly. The refineries located in the Lake Charles, Louisiana area, an area hard hit hard by the storm, and where electrical power has been extensively disrupted, are proceeding more slowly and will likely need more time to assess damage and restart operations.

Preventative closures, as well as restarts and flaring, are part of methodical procedures designed to ensure the safety of workers, communities and the environment and speak to the resilience of the refining industry and its commitment to fueling America’s economy.