Hurricane season is coming — beginning June 1 and lasting through the end of November — and with it comes unpredictable storms and heightened risks. With forecasts predicting up to 19 named storms and 10 hurricanes — the refining and petrochemical industries are prepared.

Safety isn’t just a priority; it’s a year-round commitment for these industries. But how do they ensure resilience in the face of extreme weather? By building on lessons from the past and continuously improving emergency preparedness plans to protect facilities and the communities they’re a part of.

Planning for the future

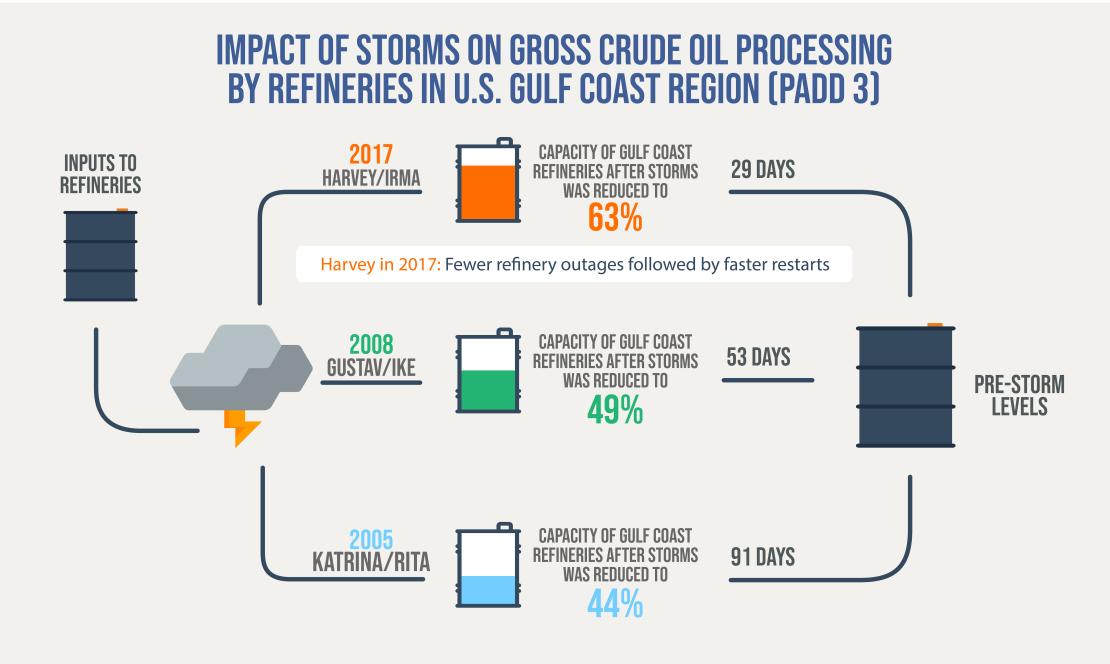

When Hurricanes Katrina and Rita hit communities twenty years ago, almost 25% of total U.S. refining capacity was impacted. It took more than 90 days for some facilities to resume operations at pre-storm levels.

However, improved risk management procedures have significantly reduced downtime in subsequent storms. In 2008, Hurricanes Gustav and Ike disrupted 49% of PADD 3 refining capacity, but operations returned to pre-storm levels in less than 60 days. Then, in 2017, Hurricanes Harvey and Irma impacted 63% of PADD 3 refining capacity. Facilities returned to normal operations in just a month.

Our industries have made great strides in strengthening their preparedness and recovery plans for future hurricane seasons. Companies share their experiences and insights with industry peers while also collaborating with government agencies and local first responders. These plans set procedures across several areas, including recovery operations, startup/shutdown events, emergency management teams, facility security, logistics, communications, personnel support and government and community relations.

To further enhance resilience, sites have also built and upgraded technologies and equipment in anticipation of future weather events, including more compressors, pumps, raised or hardened refinery control rooms, raised electrical equipment and power supplies. Additionally, on-site containment facilities have been expanded to prevent materials from escaping into the environment. Drones, or unmanned aircraft systems, are also used at facilities to identify and mitigate risks, and reduce human exposure to hazardous environments, after a severe weather event.

Helping our workforce and communities

The safety and well-being of the workforce is a top priority for refiners and petrochemical manufacturers, and our members also invest heavily in their communities in times of crisis. Our member companies contribute millions of dollars to humanitarian organizations like the Red Cross, but their support goes beyond financial aid. Many establish crisis centers to support their employees and communities, and their workforce steps up—volunteering time and resources to help their neighbors recover and rebuild after a storm.

Our member companies have provided a range of support, including:

- Collaborating with FEMA and other government agencies

- Pumping floodwater from neighborhoods

- Arranging short- and long-term housing for employees

- Helping with medical expenses

- Leveraging company engineers to help city officials restore tap water to homes

- Securing rental vehicles for employees who lost or damaged theirs

- Deploying company maintenance crews to assist employees with clean-up and repair of their homes

- Delivering convoys of supplies to affected areas

Access to liquid fuels and petrochemicals means access to energy and everyday products that make our lives better. Our facilities play a critical role in safeguarding these resources, working proactively to prepare for severe weather events. Through close collaboration with agencies, first responders and local communities, they help to protect lives and ensure the resilience of our supply chains.

For more information on how our facilities ready themselves for hurricanes and other severe weather events, as well a list of federal and state resources on storm preparedness, please visit our "Preparing for Disruption" page.

The American Fuel & Petrochemical Manufacturers (AFPM) is the leading trade association representing the makers of the fuels that keep us moving, the petrochemicals that are the essential building blocks for modern life, and the midstream companies that get our feedstocks and products where they need to go. We make the products that make life better, safer and more sustainable — we make progress.