The fuel and petrochemical manufacturing industries have come a long way from the simple thermal stills used to create kerosene in the 19th century to today’s sophisticated, high-tech and complex facilities that help provide America — and the world — with the fuels, petrochemicals and products that we all rely upon every day.

Throughout their 150-year history, these industries have developed a culture of innovation, ingenuity and grit that has helped them continue to evolve and thrive during economic expansions and to survive world wars, economic contractions and massive shifts in consumer behavior.

The birth of the industries

The refining industry was created when inventors looked at what was considered useless crude oil and turned it into a lighting replacement for whale oil. In the more than a century since then, the refining and petrochemical industries have continued to come up with new ways to repurpose and make each drop of oil and natural gas into products that underpin virtually every aspect of our modern lives — from transportation fuels that keep us moving to critical personal protective equipment (PPE) and medical supplies.

19th Century

In 1850 the first modern U.S. refinery — a one-barrel still — was built in Pittsburgh, Pennsylvania. This first modern refinery used a simple heat source to separate out kerosene, which quickly replaced whale oil as the preferred fuel for lamps and lighting.

Key dates:

1855: A Connecticut refiner distills petroleum to obtain tar, naphthalene, gasoline and various solvents.

1855: A Connecticut refiner distills petroleum to obtain tar, naphthalene, gasoline and various solvents.

1862: First internal combustion automobile is created

1862: John D. Rockefeller finances his first refinery

1879: Thomas Edison patents the incandescent light bulb

1880s U.S.-based Standard Oil produces kerosene and ships it around the world

1900s – 1930s

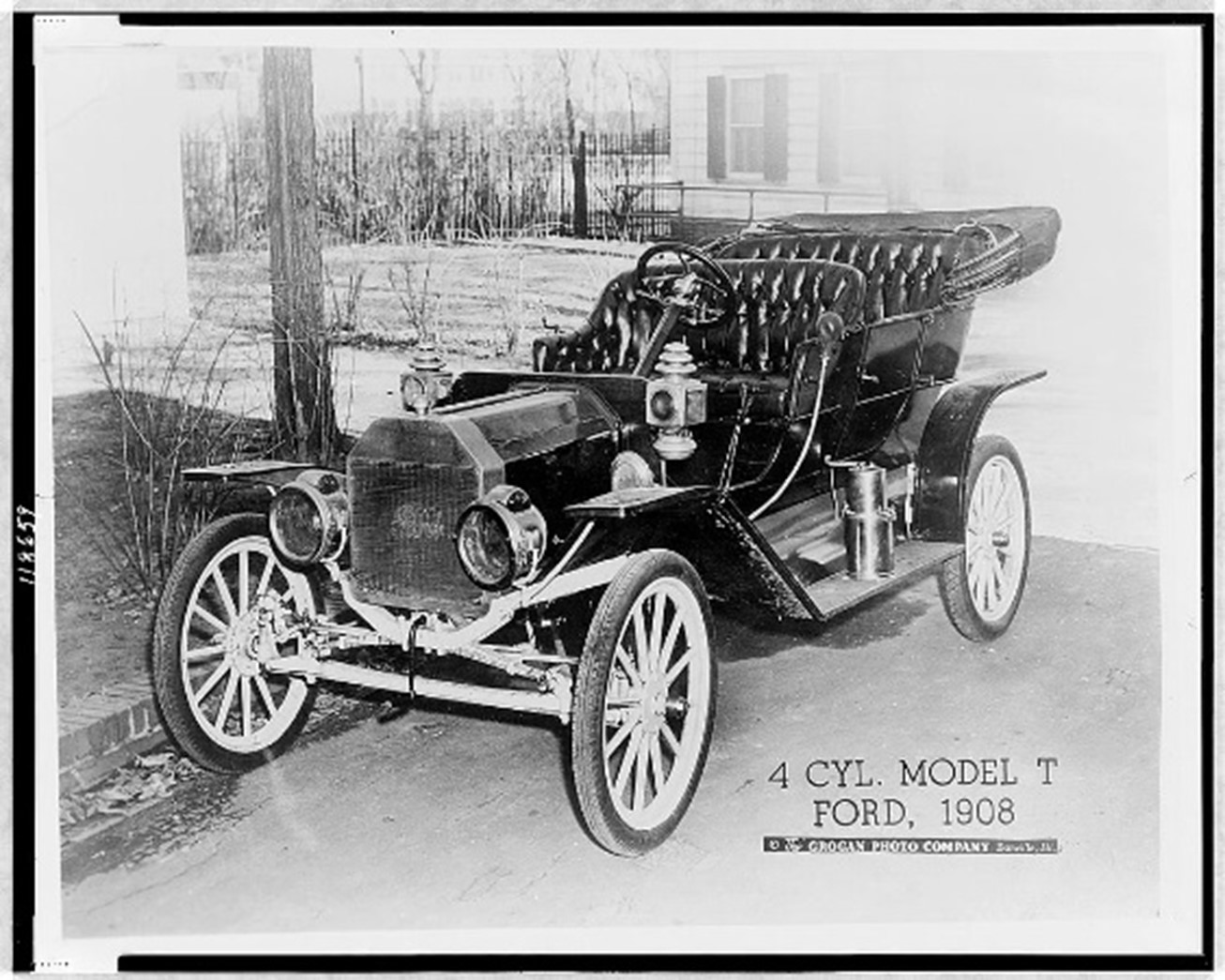

As new modes of transportation developed, refiners created new kinds of fuels — including gasoline, diesel and jet fuel — to optimize the performance of different engines and configurations. Inventors also used petroleum to develop lubricants and waxes that helped a range of manufactured products function more efficiently.

By 1910, demand for automobile fuel overtook kerosene demand. Refineries began using thermal cracking, discovered by an engineer at Standard Oil — the predecessor to ExxonMobil, Chevron and Marathon Petroleum — to produce more gasoline. Catalytic cracking was subsequently invented in the 1920s, which allowed for higher-octane products.

By 1910, demand for automobile fuel overtook kerosene demand. Refineries began using thermal cracking, discovered by an engineer at Standard Oil — the predecessor to ExxonMobil, Chevron and Marathon Petroleum — to produce more gasoline. Catalytic cracking was subsequently invented in the 1920s, which allowed for higher-octane products.

World War I further heightened fuel demand, as the U.S. military deployed aircraft, ships and armored vehicles. And the increasing use of trucks, buses, automobiles and tractors kept fuel demand surging after the war ended.

During this time, demand arose for other non-fuel products made from petroleum. These products,

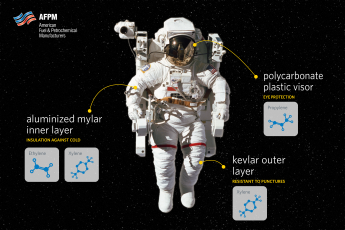

known as petrochemicals, became important for industrial processes and critical building blocks for many products used in everyday life. A number of items still common today — including Styrofoam (created from the petrochemicals ethylene and benzene), PVC (created from ethylene), plastic cling wrap and isopropyl alcohol (created from propylene) – were invented during the first half of the 20th Century.

Key dates:

1902: The National Petroleum Association – the precursor to the American Fuel & Petrochemical Manufacturers – is founded

1913: Thermal cracking is invented

1920: Isopropyl alcohol produced at Standard Oil's Bayway, New Jersey, plant is the first commercial petrochemical

1940s: Styrofoam and Saran-wrap are developed

Fledgling industries gain national prominence

1940s

The 1940s saw an acceleration in petrochemical and refining technologies and the scaling of their operations, largely driven by these industries’ crucial role in enabling Allied victories in World War II.

The use of catalytic cracking of heavy oils, alkylation, polymerization, and isomerization enabled the U.S. petroleum industry to make higher-performance fuels and meet the Allies’ need for aviation, truck, jeep, motorcycle, and tank fuels as well as providing lubricants for Allied weapons and machinery. The petrochemical industry, meanwhile, was critical in creating synthetic rubber for vehicle tires (created from butadiene), TNT (made from toluene), polyvinylidene chloride liners for combat boots (made from ethylene), insulation for radar and underwater cables (ethylene again), among many other items.

The U.S. provided a strategic advantage to the Allies since it produced 60 percent of the world’s crude oil, but the predominant use of shipping to transport oil and fuels left the country vulnerable to German U-boats — which patrolled the Atlantic in an effort to keep those critical fuels from reaching the battlefield. In order to mitigate this threat, the U.S. government-funded the longest and largest pipeline created up until that point: the War Emergency Pipeline ran from Baytown, Texas, to Linden, New Jersey.

Continued innovation also drove the increasing adoption of petrochemicals in consumer products. These products would appear with increasing frequency on store shelves until consumer products without some petrochemical application became the exception and not the rule.

Key dates:

1940: Standard Oil develops catalytic reforming to produce higher octane gasoline and creates toluene for TNT

1940: First tire from synthetic rubber produced in U.S.

1940: Women’s nylon stockings are first sold commercially in the U.S.

1941: Dow scientist invents Styrofoam

1942: Inventors at Exxon develop fluid catalytic cracking, a process that now produces the majority of the world’s gasoline

1942: Polyester resins are introduced

1942-43: War Emergency Pipelines that link Texas and New Jersey constructed to move crude oil and refined products to fuel war efforts

The 1950s and 60s

The post-war era brought unparalleled prosperity to Americans. A national interstate system, the rise of the suburbs, and the increasing affordability of vehicles all combined to propel car ownership to dizzying new heights, while air travel took off as an accessible way to travel the world. At the same time, petrochemicals enabled the widespread use of luxuries and conveniences — including new synthetic fabric clothing, home furnishings, and accessories.

To meet this increasingly varied consumer demand, the refining industry continued to become more advanced and complex. Many facilities began using hydrocracking, which allowed for a broader range of end products.

As the industries expanded, so did the transportation systems to handle feedstocks and finished products. The construction of what is now termed “midstream infrastructure” — the system of pipelines, ports, railroads, roadways and storage systems needed to transport America’s energy supplies from producer to consumer — echoed the construction of the interstate highway system. The midstream petroleum transportation system enabled refineries to consolidate and benefit from economies of scale since they could now efficiently transport crude oil and natural gas — as well as the fuels and other products they produced — throughout the country.

The intensely competitive nature of the fuel and petrochemical industries during this time made innovation an imperative. As a result, major corporations created advanced research and development departments, where scientists invented new products including engineered polymers, block copolymers, a wider variety of polyesters and polyurethanes and various molecular weight polyethylenes, all from the same six base petrochemicals — as well as laying the groundwork for breakthroughs such as the lithium-ion battery.

Key dates:

1950: Benzene is produced from petroleum

1954: Polyisoprene rubber — a key component in numerous medical devices — is developed

1954: Synthetic zeolites, which further advance the cracking process, are developed

1960: OPEC is created

1965: Kevlar is invented

1968: Man-made fibers outsell natural fibers in the US

1968: Ziploc bags are introduced

1970s, 1980s, and 1990s

Like other manufacturing sectors, the fuel and petrochemical industries suffer during economic downturns and periods of geopolitical turmoil, particularly those like the 1973 oil embargo that result in oil price shocks. Geopolitical turmoil had affected oil prices for much of the 1970s, resulting in repeated gasoline rationing and hindering economic growth.

The high oil prices of the 1970s were quickly followed by an oil glut in the 1980s, as the world rebounded from the oil embargo and refiners and petrochemical companies found themselves adapting to face drastically different market conditions.

Increased vehicle fuel efficiency, among other factors, led to reduced demand just as new, non-OPEC extraction projects began producing significant amounts of oil in Siberia, the North Sea, Alaska and the Gulf Coast.

The resulting market conditions led to extensive consolidation in the U.S. refining industry, with the number of refineries decreasing from 319 in 1980 to 205 in 1990. Many of the refineries that closed were small, independent operations that lacked the processing adaptability of their larger competitors. The refineries that survived continued to invest in ever-more-complex and sophisticated processing capabilities.

The turmoil continued in the 1990s, when the refining industry went through another difficult economic contraction, transforming again through extensive mergers and acquisitions. The industries as a whole became leaner and more resilient, better able to weather a variety of market and supply conditions.

This extended period of uncertainty and transition helped strengthen characteristics that still mark the fuel and petrochemical industries today: flexibility, optimism, mental toughness and a constant focus on innovating to meet the next challenge.

Key dates:

1973-74: Oil embargo

1981: Price and allocation controls for domestically produced crude and gasoline ends

1986: Crude oil price collapse

1989: EPA sets seasonal fuel volatility limits on gasoline

1989: Fall of the Berlin Wall

1990: The Iraqi invasion of Kuwait drives oil prices from $21 a barrel in July to over $40 a barrel in October

Industries embrace globalization

2000s and 2010s

In 1970, the U.S. production of crude oil averaged 9.6 million barrels per day. By 2007, U.S. crude oil production had declined to 5 million barrels per day. But the widespread adoption of hydraulic fracturing technology in the United States halted the decline in U.S. crude oil production, altering the country’s increasing reliance on imports of oil and natural gas. It turned the United States into a major player in the international energy markets and the leading exporter of liquid petroleum products. The so-called shale revolution also provided U.S. petrochemical manufacturers with increased access to affordable feedstocks, which they used to create the chemical building blocks that enable the manufacturing of a broad range of consumer products increasingly demanded by an ever-growing global middle class seeking the conveniences of a modern standard of living. We are now one of the lowest-cost producers of ethylene in the world.

U.S. refineries also benefitted from globalization, using their complex facilities to transform low-value crude oil imported from trade partners into highly desirable refined products that were sold both domestically and abroad.

These industry expansions were accompanied by continued improvements in environmental performance. Facility emissions of hazardous air pollutants fell 66 percent from 1990 to 2013. And as of 2016, refinery emissions for the six criteria pollutants are down nearly 70 percent compared to 1990.

And fuel and petrochemical manufacturers are continuing to innovate to meet future challenges. Petrochemical companies have invested significantly in molecular recycling technology, which allows plastics to be repeatedly recycled, as well as launching initiatives to reduce mismanaged plastic waste. Companies are researching new ways to capture carbon at facilities and developing new engine oils that reduce friction and boost gas mileage. They are also creating more durable, lightweight and environmentally-friendly answers to the world’s need for sanitary packaging, safe transportation and next-generation medical solutions.

Meanwhile, U.S. refiners invested over $100 billion to make their facilities among the most efficient and complex in the world, positioning themselves to deliver the cleaner fuels required by today’s consumers. And petrochemical companies invested $185 billion from 1988 – 2018 to help more efficiently meet the world’s need for their products.

In an effort to deliver still higher-performing and lower-emission fuels to American drivers, AFPM for the last several years has advocated for a high-octane 95-RON fuel performance standard. This 95-RON standard would deliver significant efficiency improvements in new vehicles, yielding substantial reductions in carbon emissions across the vehicle fleet. When paired with automobiles optimized for such fuel, 95-RON can deliver a 3 – 4 percent fuel efficiency gain and have the carbon-reduction equivalency of taking hundreds of thousands of vehicles off the road each year. This 95-RON fuel could be sold using the nation’s existing fueling infrastructure, not requiring the significant investments needed for electric vehicle charging stations and infrastructure - and it is compatible with vehicles on the road today.

Key Dates:

2010: Occidental Petroleum opens its Century carbon capture plant in Texas

2015: Congress lifts oil export ban

2016: AFPM begins advocating for a 95-RON fuel standard

2017: World’s first commercial direct air capture carbon capture facility opens

2019: The United States becomes a net energy exporter

2019: INEOS produces virgin polystyrene from recycled styrene monomers, providing practical proof of the molecular recyclability of polystyrene

2019: Eastman announces the ability to molecularly recycle polyester and complex plastics

2020 and beyond

Like many other industries, fuel and petrochemical manufacturers have faced unprecedented challenges in 2020. These industries — deemed “critical” by the Department of Homeland Security — are integral parts of the effort to fight the COVID-19 pandemic.

Our industries continue to provide everything from the fuel needed by emergency vehicles to the petrochemicals used in PPE and hand sanitizer, despite significant market disruptions and challenges. Moreover, companies have demonstrated their adaptability and commitment by pivoting to ramp up in record time, meeting the need for frontline equipment essential for the fight against COVID-19.

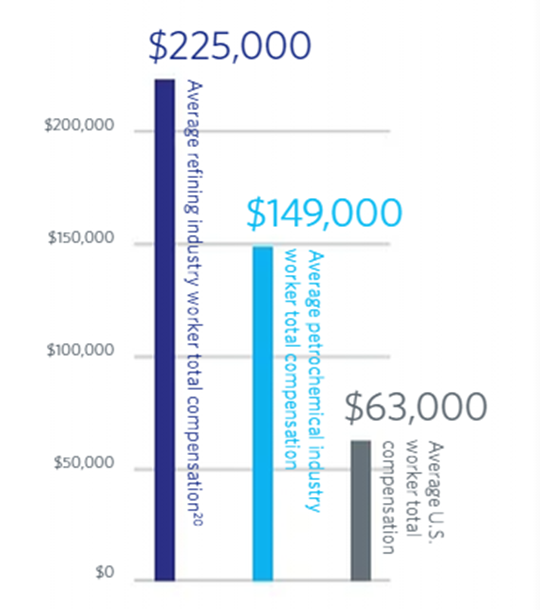

Though our industries have seen their fair share of tough times over the past century, we continue to provide the energy that is the lifeblood of the U.S. economy. And our industries support 3.5 million highly skilled, particularly well-paying jobs across all 50 states. In fact, industry compensation is roughly two to three times that of the average for U.S. workers.

Though our industries have seen their fair share of tough times over the past century, we continue to provide the energy that is the lifeblood of the U.S. economy. And our industries support 3.5 million highly skilled, particularly well-paying jobs across all 50 states. In fact, industry compensation is roughly two to three times that of the average for U.S. workers.

Fuel and petrochemical manufacturers also significantly add to the tax base. In 2018, our industries contributed over $60 billion in federal taxes and nearly $70 billion in state and local taxes — enabling the funding of essential services at the state and local levels.

And the economic benefits provided by our industries won’t go away anytime soon. The U.N. estimates that the world’s population will grow by 2 billion people in the coming decades, and access to affordable energy will remain vital to human progress. The U.S. Energy Information Administration says global energy consumption will increase by nearly 50 percent by 2050 and that petroleum will supply more than three-quarters of global transportation energy consumption.

Even as new advanced energy technologies come online, the jobs we provide will continue to be essential. A recent survey by NATBU found that oil and natural gas jobs are seen as offering better pay, benefits and career opportunities than renewable jobs. And despite the current economic downturn, companies are continuing to invest in internships, apprenticeships and efforts to diversify the workforce, positioning them for challenges and opportunities ahead.

That’s one of the reasons the industries have invested heavily in cleaner fuel production, molecular recycling, plastic waste reduction efforts, and more efficient and environmentally friendly production methods: We know we’ll our essential products will be relied upon for, and we want to continue to make the world a better place.