The U.S. refining industry today looks a bit different than it did pre-pandemic. We have less total refining capacity and fewer operable refineries producing essential fuel than we did just a few years ago. And since demand for fuel products remains strong, we rely even more on America’s slightly leaner refining kit to satisfy U.S. and global needs for gasoline, diesel, jet fuel and other refined products. But to keep U.S. facilities online and operating safely requires upkeep, both in the form of ongoing maintenance and much more intensive refurbishment and replacement projects. The latter, which are known as turnarounds, involve taking all or parts of facilities offline for planned periods of time to conduct essential site upkeep, extensive maintenance and construction, and other improvement projects with specialized professionals.

Turnarounds—and the time they require—are critical for safe refinery operations and for the longer-term reliability of U.S. fuel production. But with a smaller number of U.S. facilities shouldering market demands, offline facilities can impact market dynamics. Where turnarounds are concerned, though, refineries take every measure possible to limit any potential disruptions to consumers and fuel supplies.

What is a turnaround?

Simply put, a turnaround is a planned period of extensive maintenance, renovation and capital investment at a refinery or other major manufacturing installation. Turnarounds happen, often at regular intervals, in addition to the routine maintenance and upkeep refineries receive on a daily basis when they’re in operation. Depending on the scale of turnarounds, facilities can go “offline” entirely for a stretch of weeks or scale back operations at one or more process units for a duration of time to complete inspections, maintenance and building projects. Either way, facility utilization and product outputs will be reduced while in turnaround.

You can think of a turnaround as similar to performing major maintenance on your car. While car owners regularly fill up their gas tanks, check fluid levels and change the oil every few thousand miles, there will be incremental times when cars require more thorough servicing and tune-ups. That’s true for refineries too, but because of the scale of our operations, routine maintenance for us amounts to massive investments of time and resources.

Why do facilities need to go into turnaround?

Turnarounds are essential. Enhanced inspections and equipment replacements, which are all part of the turnaround process, enable refineries to operate safely, comply with government regulations and stay competitive in a fierce global market.

Is a turnaround the same as a refinery outage?

Refineries in turnaround might be classified as having an outage, but the key distinction is that turnarounds are planned. Refineries can go offline temporarily for unplanned maintenance to address specific issues in specific units, but these unplanned outages are typically shorter in duration than a turnaround.

What’s involved in preparing for a turnaround?

Because of the size of fuel refining operations, the scope of potential turnaround projects and the essential role each facility plays in the global fuel market, individual refinery turnarounds require extensive planning. Turnaround planning teams often begin their work years ahead of when an actual turnaround project is slated to kick off. Teams start by assessing the extent of likely maintenance needs on site and other potential projects to tackle while facility operations are reduced or offline. Then, with those specific projects in mind, they build out a budget and timeline, detailing all necessary equipment and specialized labor support that might be needed to execute the turnaround. They also begin developing alternative supply plans to make sure, as best as they are able, that any time a facility spends offline doesn’t leave customers without essential fuel. This last part is key! Turnarounds are carefully planned, often for periods of time where fuel demand is typically lower, to minimize any potential market impacts.

When do turnarounds happen?

Facilities maintain their own turnaround schedules and do not broadcast or coordinate them with other refineries. Still, you’ll notice that refineries don’t all go offline for turnarounds at the same time. That’s because most are on a three- to five-year turnaround cycle. This means that every three, four or five years a facility will undergo extensive routine maintenance. Given the amount of planning and the limited pool of highly specialized workers required to staff refinery turnarounds (primarily outside consultants and crews that perform work across the industry), it’s simply not possible for every refinery to go into turnaround at once.

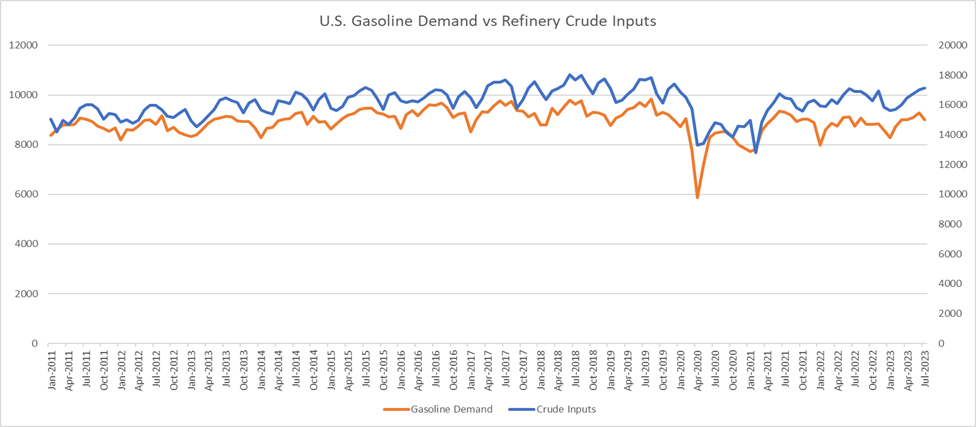

There are noted “turnaround seasons” in the refining industry. In the United States, turnarounds typically happen in the spring or fall, pre- and post- summer driving season, when demand for gasoline is lower. Scheduling turnarounds during periods of seasonally low demand minimizes disruptions to customers and the larger market (see chart below).

How long does a turnaround last?

The short answer is it depends. Turnaround timelines can range from a matter of weeks to a matter of months, depending on the complexity of all the planned projects. For a series of complex projects, turnarounds can involve more than a million man-hours over the course of a couple months to complete all scheduled work.

Bottom line, turnarounds are a normal part of refinery operations. They are essential and are conducted to help facilities perform as efficiently and as safely as possible, and they are scheduled, wherever possible, during periods of lower fuel demand to reduce impact on the market and fuel consumers.

The American Fuel & Petrochemical Manufacturers (AFPM) is the leading trade association representing the makers of the fuels that keep us moving, the petrochemicals that are the essential building blocks for modern life, and the midstream companies that get our feedstocks and products where they need to go. We make the products that make life better, safer and more sustainable — we make progress.