Question 68: What is a typical duration of online spalling of the coker furnace? What are the guidelines on maximum steam velocity during online spall?

Rajkumar Ghosh (Indian Oil Corporation)

Typical duration of online spalling is 16-24 hrs per pass of the heater.

Prima facie, the spalling operation is dovetailed with the coke drum cycle. We try to avoid continuing with the online spall during the changeover operation. This is to eliminate any chances of foam-over or coke carryover to fractionators. We start the spalling of a pass within 3- 4 hrs of drum switch and call it off prior to next switch. This gives us ~17-19 hrs in a 24 hr cycle. Change-over of feed to spalling media and reverse is not coincided with the drum switch to prevent causing any operational upsets in the coke drums.

But with refinery’s imperative of maximizing feed and with reduced coke drum cycles, we have continued with the spall operation even during the coke drum changeover without any significant negative experience. Due to the possibility of upsets during the change-over from feed to spalling media and vice a versa, precautionary addition of antifoam at the coking drums is recommended for 10-15 minutes before and after the change-over. This is to ensure that there is no carry-over from coke drums to the fractionator due to process upsets.

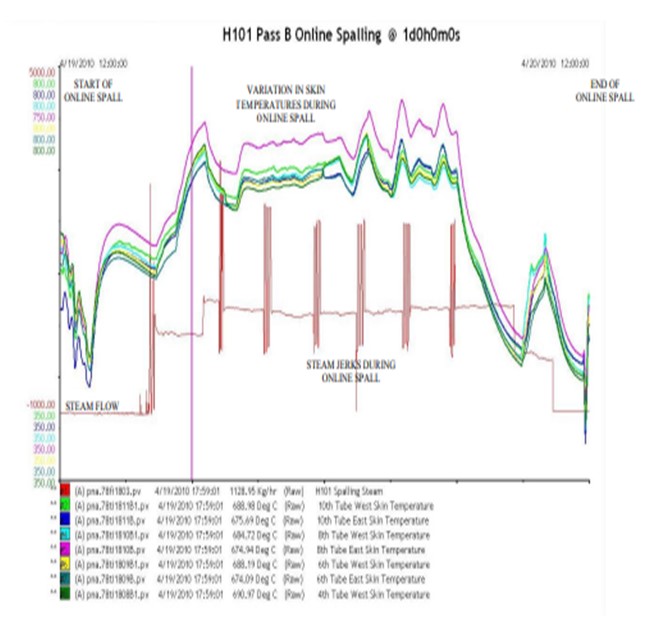

Typical flow rates and skin temperatures of a pass being spalled, trend attached below:

We use a combination of BFW and steam as spalling media, with BFW injection at convection inlet to cool convection section properly. Combined flue gas continues to be hot from other passes, which are operating as usual and BFW helps cooling the convection section of the pass being spalled. Steam is injected at the cross- over.

In our Coker, with 4” diameter heater tubes, we use about 4200 Kg/hr of spalling medium with max flow going up to 5000 Kg/hr during the intermittent jerks. The ratio of BFW to steam is about 65:35. The spalling media rate is dependent on coil size. Mass flux is of importance here. Typically, the value is 25-30 lb/sec/ft2 . However, it could be higher for a smaller duration. Aggressive spalling can lead to excessive erosion of the fittings such as the heater u-bends and the outlet header.

While increasing the spalling medium quantity during the course of spalling, we use coil inlet pressure of the coil being spalled as the guiding factor. We observe the coil inlet pressure; watch for any excessive increase in this pressure (2 kg/cm2 increase would be considered excessive) and adjust the spalling medium accordingly. If the pressure remains elevated for 15 to 20 minutes, we decrease the spalling medium to the initial rates used when starting the procedure.

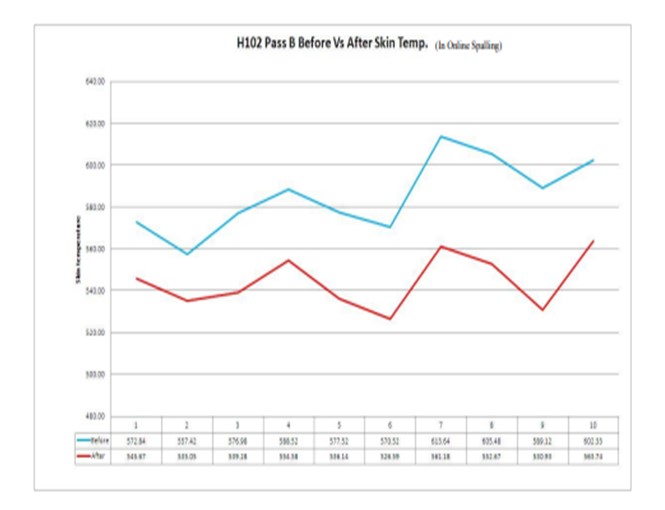

Below attached is a graph showing the gain in skin temperatures that we could achieve during online spall for a particular pass: