More than half of the 24 U.S. refineries that preventatively shut or slowed down before the arrival of Hurricane Harvey are now working to fully restore operations and resume feeding distribution pipelines, part of their mission to supply America’s economy with fuels crucial for commerce.

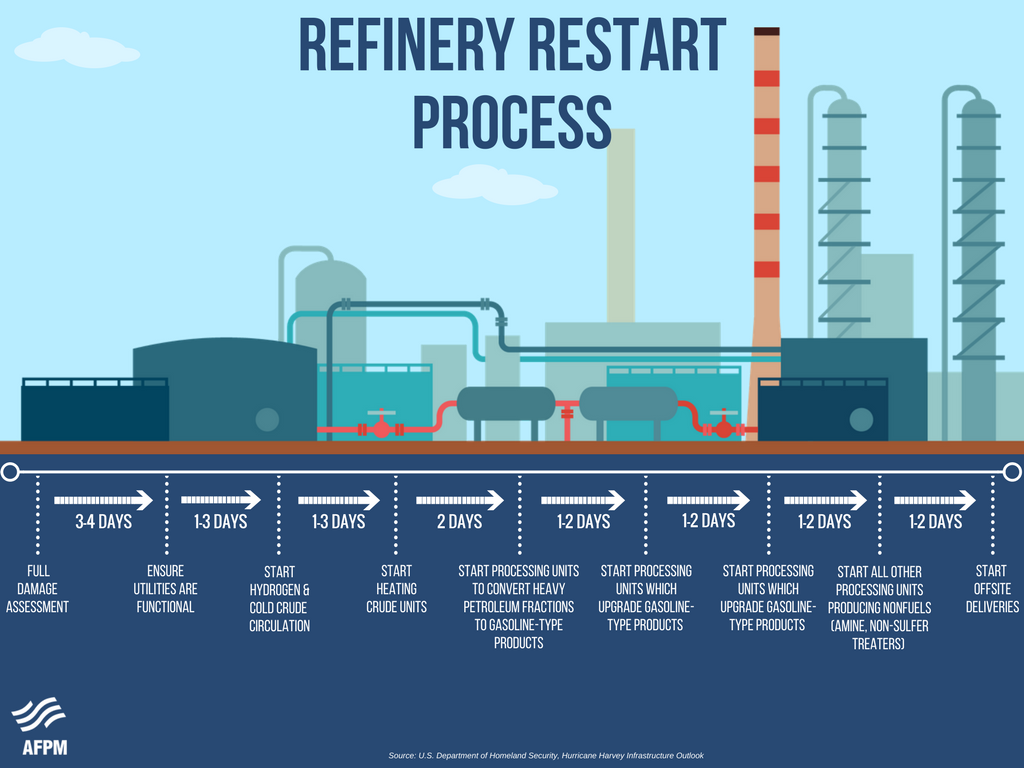

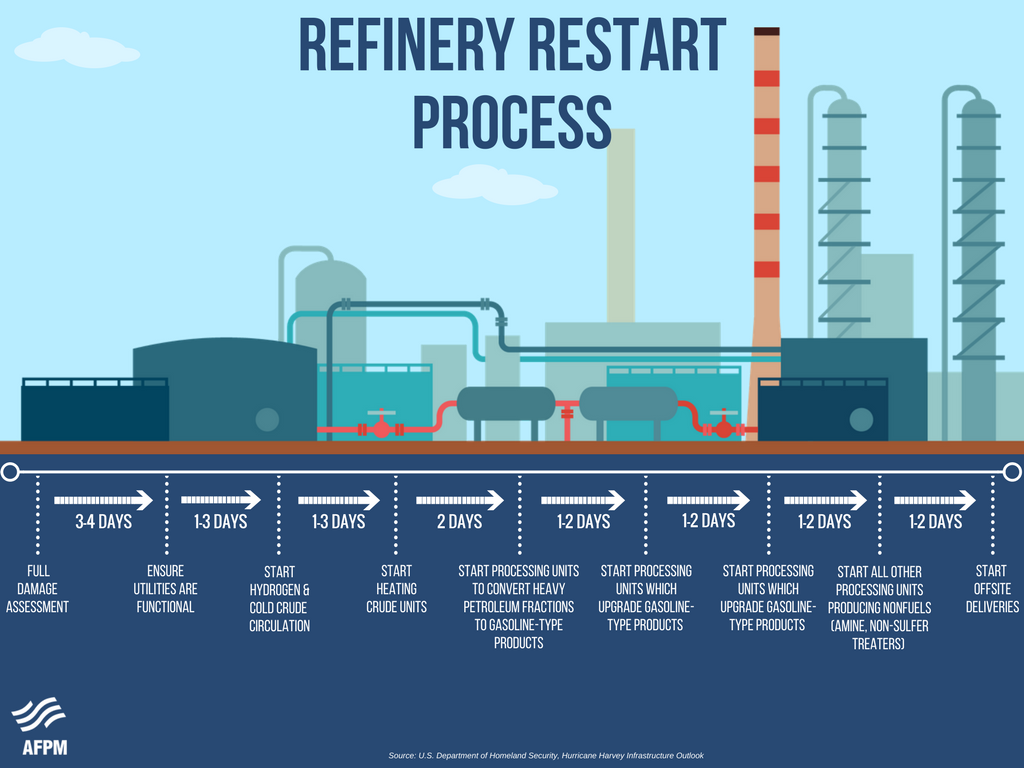

Restarts are much more complicated than flipping on a light switch. They take time. Like shutdowns, restarts must be done slowly and deliberately, according to well-defined operating procedures to protect the health and safety of refinery employees, as well as the surrounding communities and environment.

Restarts include securing safe access to the site, and checking the integrity of equipment including storage tanks, process units, piping systems, pumps and instrumentation. They also include conducting a complete pre-startup safety review that will include inspecting facilities for any storm damage, completing required management of change reviews prior to making any necessary repairs, and verifying that there are sufficient feedstocks such as oil and natural gas available for processing from ports and pipelines. Inbound supplies must be able to arrive at the refinery and outbound products must have a clear route to market, so transportation infrastructure is also examined before opening.

During hurricanes, “ride-out” crews remain on site to monitor the plants. After storms pass and as soon as all facilities are determined to be safe, crews move to energize electrical systems – if the site lost power – and cautiously ramp up activity in process units to begin turning raw materials to into products such as diesel, gasoline and jet fuel.

The good news is that refineries and petrochemical facilities in the path of the extreme weather – from Corpus Christi, Texas to Lakes Charles, Louisiana – have withstood many extreme storms. Also, thorough preparedness plans for unexpected events are developed well in advance in coordination with the government and local communities, including first-responders. These plans are updated regularly, on top of ongoing, incremental process and facility improvements. Employees at these facilities understand how important following well-established processes is to their own safety and that of the larger facility.

As the floodwaters recede, America’s fuel and petrochemical manufacturers are moving towards safely restarting their facilities and again manufacturing the fuels and products we need as part of our everyday lives.