Question 9: Are you adding unusual feeds to catalytic condensation or oligomerization units?

GAYL MERCADO (Axens North America)

Refiners have been pursuing the use of more atypical feeds to their olefin oligomerization units for various reasons. Units have historically operated on FCC LPG cuts, but an interest to process Coker LPGs or even heavier FCC olefins have begun.

The use of these alternative feeds has historically been limited by several factors, but newer catalyst generations and types have allowed a wider envelope of feeds while maintaining stable operation with long cycle lengths.

Refiners have been looking to a propane/propylene (PP) cut to units processing heavier materials. As well, options to remove C5s from the gasoline pool through oligomerization to heavier material can make sense where refiners find themselves long on light material in the pool, ultimately reducing the RVP of final blend.

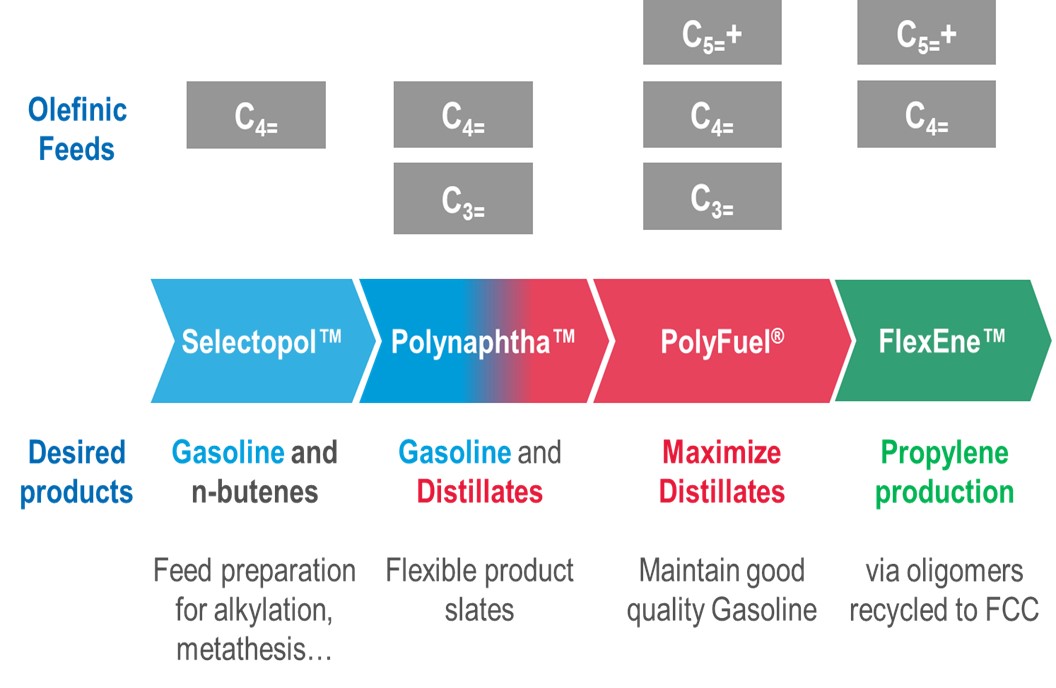

Within Axens, the oligomerization suite of technologies was developed around a single robust catalyst, that can operate in wide range of environments and with various feed qualities.

When operating with traditional FCC and Coker LPGs, the PolynaphthaTM focuses on converting into gasoline and middle distillates, providing an economical solution for refiners to tackle the unbalanced gasoline/middle distillates slates. When looking to maximize octane, the SelectopolTM technology targets conversion of only the isobutene portion of an olefinic C4 fraction to either produce a high octane, low RVP gasoline blending stock or to produce a trimethyl pentene stream for petrochemical applications. The enriched n-butene product is an ideal feed to an alkylation unit without requiring any pretreatment. Lastly, the PolyFuelTM technology expands on the operation of lighter cuts by the co-processing, or even direct processing of heavier olefins to produce a heavy gasoline and middle distillates at lower cost.

CHRISTIAN ARNOUX (Valero)

The opinions expressed are those of the author and do not necessarily represent the views of Valero Energy Corp.

-

An FCC Cat-Poly reactor will convert propylene and butylene into gasoline blending components

PAT BULLEN and JOCELYN DAGUIO (UOP)

UOP has not designed any units with feeds outside of C3/C4 range. We have heard from customers discussing adding C5 olefins and benzene to their existing Cat Poly units but have not received any data from this type of operation to evaluate its efficacy.