Question 88: What options exist for the disposition of FCC equilibrium catalyst and fines? For refineries processing residual feedstocks, what are the limitations on the contaminate levels for the various disposal options?

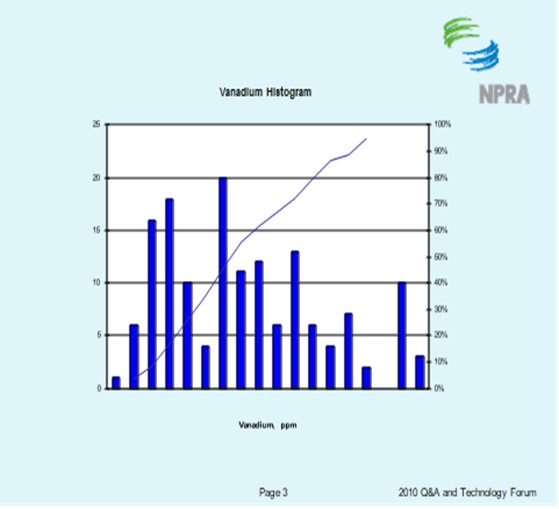

A review of all ecats BASF receives shows the following distribution of Vanadium,

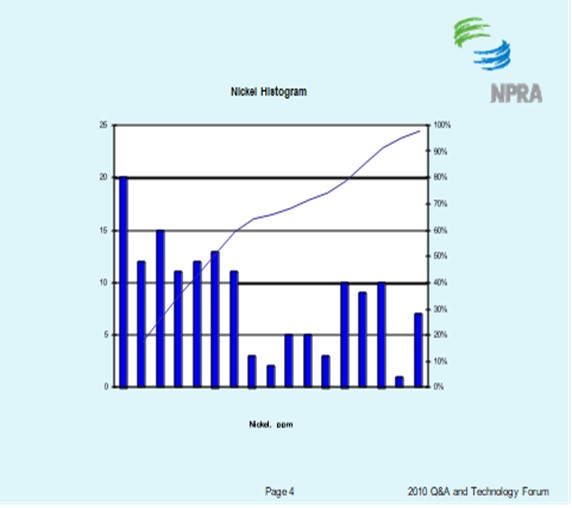

A review of all ecats BASF receives shows the following distribution of Nickel,

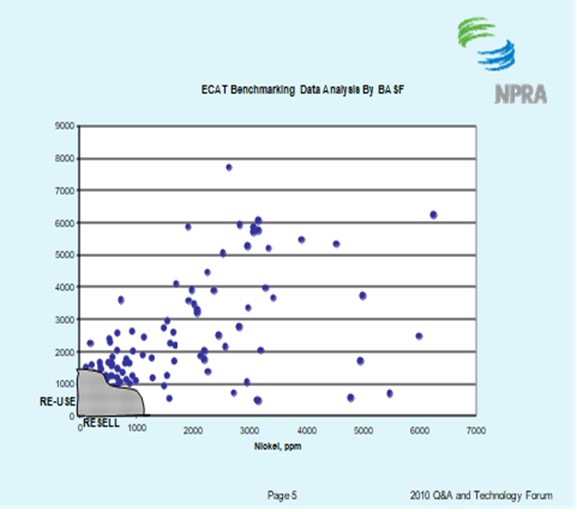

Shown below is generalized envelope for Re-sell / Re-use. This chart suggests a significant portion of ecats are recycled for use in another FCC.

Emerson Domingo (Sunoco)

E-cat and ESP hopper fines are either send to a cement kiln or land filled. Fines captured by the Wet Gas Scrubber are also land filled. Metals limits are normally for leachable metals as measured by the TCLP (Toxicity Characteristic Leaching Procedure) testing, as opposed to total metals in the catalyst.

Stuart Kipnis (Grace Davison)

There are generally three disposition options for FCC equilibrium catalyst (E-cat) and fines. 1.Selling of E-cat is an option if the quality is deemed suitable for reuse. With GRACE’s ENCORE™ program the catalyst technology is appropriately matched to another refinery’s needs. Resale of E-cat fines, normally limited to refineries in need of improved circulation is much less common.

2.Recycling of E-cat and fines through cement kilns is a common practice for material coming from residual feedstock operations where metals contamination is much higher. In most cases the material must be classified as a non-hazardous waste. [There are select kilns that are permitted for handling hazardous materials.] Claude Kennard from Metaloy states that in order to dispose of E-cat and fines at a cement kiln, the material must be non-pyrophoric. As such, most kilns will require a full TCLP analysis before accepting E-cat. Levels of nickel and vanadium are not necessarily the limiting factors for determining acceptance of E-cat for a cement kiln. As raw material requirements change, contaminants like sodium can become important. Each kiln will have unique requirements – larger units will have less constraints since the E-cat and fines are a very small percentage of raw material input.

3.The last option is to dispose of E-cat and fines at a landfill. This becomes a viable alternative when a local cement kiln is perhaps too small to accept the volume of E-cat or if there is no local kiln.