Question 85: What is your reliability experience of multi-loader and continuous additive/catalyst loaders? What maintenance do you require?

Stuart Kipnis (Grace Catalysts Technologies)

Refiners have created operating flexibility during hydrotreater outages by utilizing Grace’s clean fuels GSR® additive technology.

Proper management of FCC feed hydrotreater outages becomes increasingly important as more and more refiners rely on hydrotreating to meet their per gallon gasoline sulfur limits. Running at higher severity increases the frequency of turnarounds. Conventional methods of insuring that the gasoline pool staysbelow the sulfur limit during the hydrotreater turnaround are purchasing low sulfur feed or reducing FCC throughput. Either approach can significantly reduce refinery profitability. An alternative is to use one of Grace’s gasoline sulfur reducing technologies during the outage to provide operational flexibility while maintaining sulfur compliance and profitability.

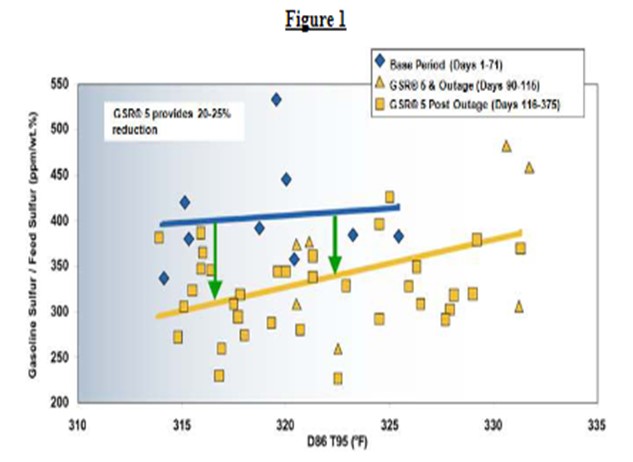

One such example of a refiner that used Grace GSR® 5 sulfur reduction additive during a feed hydrotreater outage is shown in Figure 1. The refiner was able to process higher than typical feed sulfur and maintain gasoline pool sulfur compliance. Use of GSR® 5 began two months prior to the 45-day feed hydrotreater outage. During that time, feed sulfur increased by as much as 35%. The three periods represented are typical operation (Base Period), GSR® 5 before and during the outage where gasoline sulfur reduction ranged from 20-25%, and finally GSR® 5 following the outage.

The customer estimated that use of GSR® 5 netted $1.7 millions of savings during the hydrotreater outage. The results were so encouraging that the customer elected to continue using GSR® technology, switching to a SuRCA® catalyst and operating with post outage feed sulfur 10-15% higher than the typical operation. This change to their operation grew annual profits by approximately $8 million.

Continued operation during a hydrotreater outage is just one way that refiners can benefit from application of Grace’s patented GSR® technologies. In-unit reduction of FCC gasoline sulfur creates a variety of opportunities and options for refiners to drive profitability while meeting new Tier 3 gasoline requirements.

Grace’s GSR® clean fuels solutions create economic advantages around:

• Feedstock blending

• Asset optimization to:

• Preserve octane

• Maximize throughput

• Extend pre-treatment and/or post-treatment hydrotreater life

• Gasoline stream blending options

• Generation of gasoline sulfur ABT credits to defer capital investment

Tier 3 regulations require the reduction of average gasoline pool sulfur level to ≤10 ppm with an 80-ppm cap by January 2017, compared to the current limit of ≤ 30ppm with an 80-ppm cap. Grace has substantial experience in similarly demanding environments like Japan.

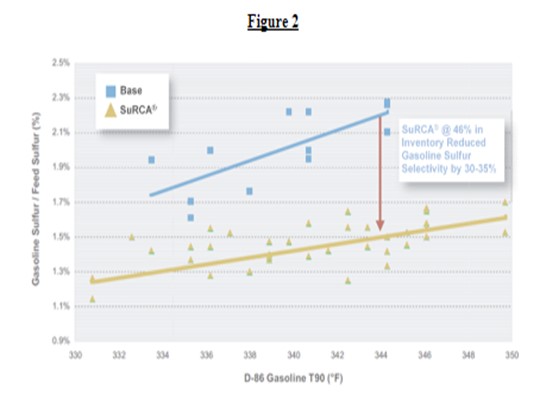

In the mid 2000’s, Japan committed to lower gasoline sulfur. As early adopters of more stringent gasoline quality regulations, Japanese refiners faced similar challenges that US refiners face today in meeting Tier 3. Since 2005, these refiners have successfully utilized Grace GSR® products to maintain compliance, observing 35%-40% reduction in the gasoline sulfur / feed sulfur ratios allowing them to meet the 10 ppm gasoline specifications. An example of a Japanese refiner meeting 10 treater severity can be seen in Figure 2. In this case, as much as 35% gasoline sulfur reduction was achieved with SuRCA® catalyst.

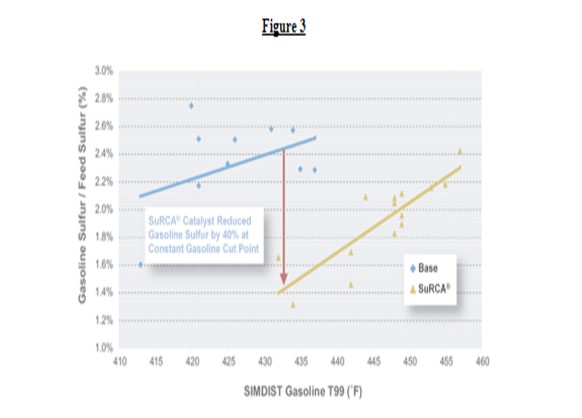

Another example [Figure 3] shows a Japanese refiner that was able to maintain compliance with the 10 ppm gasoline sulfur spec while maintaining flexibility to either blend high sulfur coker gasoline into the gasoline pool or extend the VGO hydrotreater catalyst life. Again, SuRCA®catalyst technology was and the refiner observed approximately 40% reduction in gasoline sulfur.

Grace GSR® technologies: D-PriSM result of almost two decades of innovation. Grace GSRFCC applications worldwide delivering 20%burn operations. The GSR® additive technologies are used at a 10%the catalytic solutions are a customized 100% drop can be used for short- or long-term applications; the longest continuous application is now 12 years.

Grace’s multiple product offerings allow for a truly Tier 3 compliance plan. Ask your Grace representative which product is best for your operation.

Reference: 1L. Blanchard, C. Borchert, M. Pu, NPRA Annual Meeting, 20072 L. Blanchard, T. Oishi, B. Teo, J. Haley, "SuRCARefineries", Catalagram® 98, 2005