Question 84: Please describe the function of the critical flow nozzle in relation to the operation of a third stage separator. What are the key process/operations/maintenance considerations you associate with the performance of the nozzle? Can poor performance result in a unit shutdown?

Emerson Domingo (Sunoco)

The critical flow nozzle (CFN) is located on the underflow line of the Third Stage Separator (TSS). The purpose of the critical flow nozzle is to continuously help blow down cat fines separated in the TSS. The nozzle is normally designed for 2-4% flue gas and designed to take the same pressure drop as the Expander.

The performance of the TSS can be adversely affected if the underflow line is plugged by a cracked or collapsed CFN. In that case, the catalyst backs up in the TSS and goes to the expander instead. The other mode of failure can be the erosion of the CFN holding flanges and cone, which could potentially result in leaking flue gas and catalyst to atmosphere. In either case, a shutdown may be needed if expander blade deposits and expander vibration become unmanageable or the CFN boxes kept on eroding.

Paul Hewitt (Tracerco)

Due to the relatively “dirty” nature of crude tower and main fractionator bottoms fluids nuclear gauge technologies are commonly used for continuous bottoms liquid level measurement. The main benefit of nuclear gauge technology is its non-contact design.

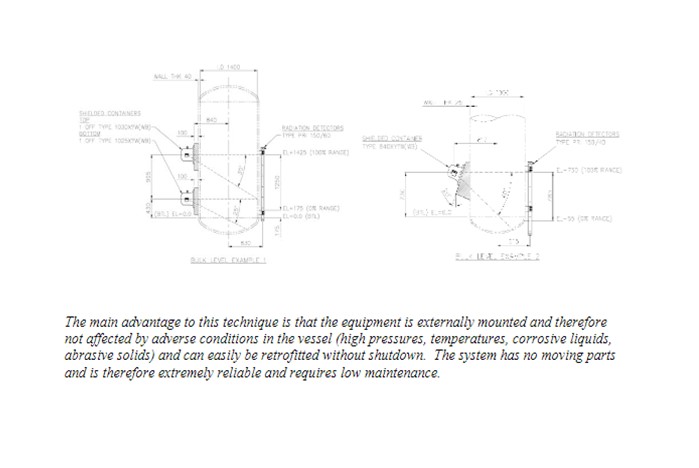

A radioactive source is housed in a lead filled container, which emits a collimated beam of radiation. When the vessel is empty this penetrates the vessel wall, across the inside of the vessel, through the other wall and is incident upon the detector. An angle is cut into the container that allows a specific vertical range to be covered. Figures 1 and 2 show general arrangement diagrams for the external source variation used for bulk level control, alarm and critical process shutdown. As the level of liquid in the vessel rises to the detector vertical position, it attenuates the radiation reaching the detector. This causes a decreasing pulse rate to be produced by the radiation detector, which is then converted into a 4-20 mA or digital signal. Typical nuclear gauge instruments typically incorporate many advanced features to enable accurate and reliable level detection, including:

•Automatic correction for radioactive source decay,

•Automatic correction for changes in vessel operating pressure,

•Linear and logarithmic linearization options for level correction,

•Extensive self-checking and error reporting facilities,

•Digital Interfaces