Question 78: What operational and catalytic changes have you implemented to optimize C4 olefin yield for the alkylation unit?

YORKLIN YANG (BASF Corporation)

The right choice of catalyst can help to improve C4 selectivity in an FCC unit including:

1. A catalyst with reduced rare earth oxide (REO), which will make more C3s and C4sbut preferentially increases butylene, and

2. A catalyst with absolute lowest possible sodium content, which will also increase butylene production over propylene.

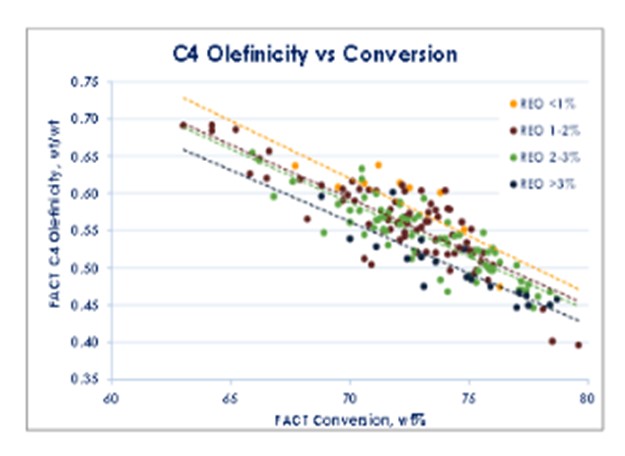

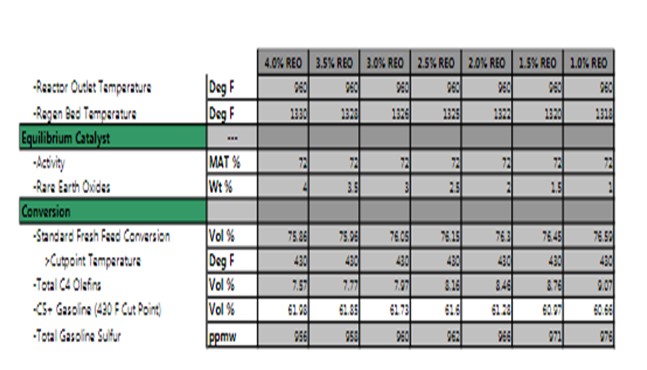

A low REO of less than 1% can yield a higher C4 olefinicity compared to catalyst of higher REO at constant conversion. However, as conversion increases, C4 olefinicity will decline. This is demonstrated in KBC modeling, shown below.

Another change is increasing riser outlet temperature (ROT). This is one of the most common adjustments to increase the production of olefins. Raising riser temperature favors production of butylene over propylene.

Lastly, to optimize C4 olefins, a refinery can optimize its ZSM-5 addition rate. ZSM-5 additives preferentially produce propylene. Typically, 60% of the incremental olefins will be propylene and only about 30% will be butylene. If using a ZSM-5 additive, by reducing the amount of ZSM-5 addition, you will increase butylene selectivity. There are also discussions in the industry on specialized ZSM-5 to increase butylene selectivity (1:1 increase versus 2:1 increase, depending on the amount of rare earth in catalyst)