Question 78: What are the locations, formation mechanisms, mitigations and removal methods for coke deposition in the riser, reactor, reactor vapor line and main column inlet nozzle?

Tom Lorsbach (UOP)

There are two ways that coke forms in FCC reactors. These are incomplete vaporization in the feed injection zone of the riser and HC vapor condensation of high boiling point species on cooler surfaces. In both cases the hydrocarbon liquid wetted on a surface has essentially infinite residence time at elevated temperature, resulting in thermal degradation reactions that create solid coke deposits. Additionally, the heavy hydrocarbon wetted surfaces tend to be sticky and it is common to find high levels of catalyst incorporated into the coke deposits. Ash from reactor coke samples are often in the range of 20 - 50 wt%. The potential for coke formation in the reactor and riser increases as feed becomes heavier and more contaminated. In addition, different riser termination devices and arrangements of reactor internals will have differing susceptibility to coke deposition. Removal of coke from risers and reactors is performed by careful mechanical chipping. High pressure water jetting has been used successfully to remove coke from reactor vapor lines.

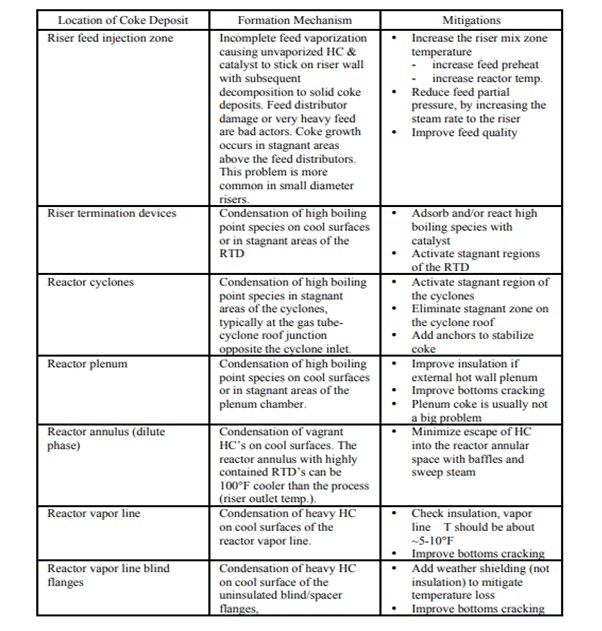

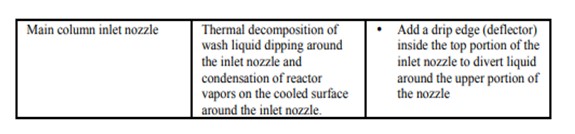

The chart below summarizes the locations, formation mechanisms and possible mitigations of coke formation in FCC reactors.

Mike Teders (Valero)

Location:

Coke found in the riser and reactor cyclones is a symptom of poor feed nozzle performance, where un-vaporized feed is subjected to high temperatures and thermally decomposes to coke. Coke found in the reactor is most likely due to inadequate dome steam used to blanket the reactor to prevent accumulation of vapor products from condensing and coking on lower temperature surfaces. Coke found in the reactor vapor line is most likely due to condensation of high molecular weight vapor at low temperature surfaces such as vapor line supports and main column nozzle attachments.

Formation Mechanism:

Coke is deposited in the FCC reactor section by a thermal process, where the raw feed has either failed to completely vaporize and participate in the catalytic cracking reaction or the high molecular weight vapor has condensed on a surface where it thermally decomposes to coke.

Mitigation:

Mitigation of coke from un-vaporized feed can be done by elevating the raw oil feed temperature to improve the feed nozzle performance. (Typically, the best practice is to limit the feed temperature in resid FCC units to no less than 425 F to ensure adequate feed vaporization.) Feed nozzle technology also plays a role in resid feed vaporization, requiring a robust design that delivers good atomization and catalyst penetration. Mitigation of coke in the reactor is accomplished from maintaining the minimum dome steam rate recommended by the technology provider (typical superficial velocity is 0.05 to 0.1 fps). Adequate insulation and weather protection on hot reactor and reactor vapor line services is also a good best practice for mitigating the formation of coke. At one location we have experienced coking in the reactor vapor line at vapor line pipe support. The support ring was a “cooling fin”, causing the condensation of high molecular weight vapor and ultimately coking. The ring was not insulated since the mechanical engineers felt that the elevated support temperature would derate the strength of the support ring. The support ring was shielded from rain by installing insulation weather protection. We also have experience with hydrotreating FCC feed making less coke in the reactor than unhydrotreated feeds. At one location we avoid low reactor temperature since experience has shown this to cause coking in the reactor cyclones. The coke formation in the low reactor temperature case is most likely caused by unvaporized high molecular weight feed.

Removal:

Not all coke is removed. Some coke is retained if it is not disruptive to the normal flow path. Coke removal is a manual operation using chipping hammers for the hard coke. In cold wall designs, the coke impregnated refractory can be indistinguishable from hard coke. If the refractory contains stainless steel needles, the chipping hammer will throw sparks when the hammer tip hits the refractory, an indication to the chipping hammer operator to stop before significant refractory is removed. We hydroblasted coke from the Main Column nozzle where the reactor vapor line enters the tower. To my knowledge we have not used any unconventional methods to remove coke.