Question 77: How do you minimize the entrainment of inerts from the regenerator which eventually enter the fuel gas system and sulfur recovery units reducing available capacity?

Steve Shimoda (SHAW)

In the Shaw RFCC, we utilize a withdrawal well design that allows the catalyst to deaerate before it enters the RCSP. The withdrawal well achieves a very high catalyst density at a stable flux. It can also help the pressure balance. Entrained inerts are defined by the following equation:

Entrained Gas Calculation:

ACFSgas = (ccr / ρsp) x (1 - ρsp / ρsk)

Where:

ccr = catalyst circulation rate, lb/s

ρsp = mixture density in standpipe, lb/cf

ρsk = catalyst skeletal density, lb/cf

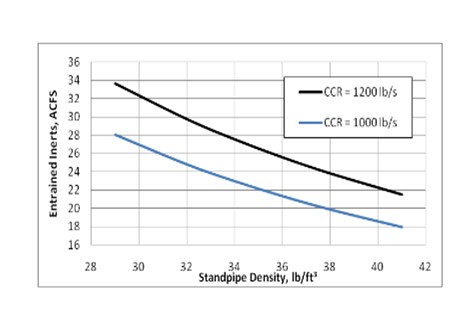

From the equation it’s easy to see that inerts can be minimized by reducing catalyst circulation rate or increasing the catalyst density in the standpipe. Reducing the catalyst circulation will linearly reduce the amount of inerts. Generally, this will not provide a good overall solution for the cat cracker. By adjusting the standpipe aeration, the density in the standpipe can be increased and the entrained inerts will decrease as shown in the following graph.

Another option to minimize inerts would be to displace them with steam. However, there will be a penalty of catalyst deactivation. The catalyst deactivation in the presence of steam is particularly noticeable at high regenerator temperatures and high metals on catalyst loading.