Question 76: What has been your experience with respect to FCC flue gas analyzers using tunable diode lasers or alternatives? Any specific advantages of tunable diode laser (TDL) analyzers with respect to installation, operational service requirements, and/or reliability?

SINGH (Indian Oil Corporation Limited)

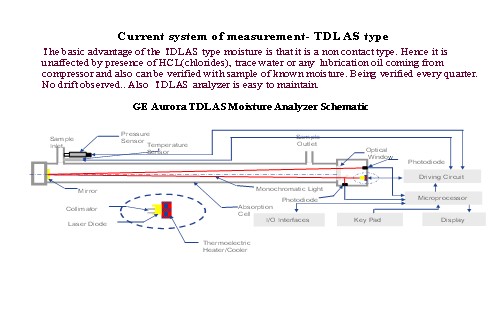

Presently, we are not using any tunable diode laser analyzers for FCC units. We typically use ultraviolet or infrared analyzers which have their own reliability issues and have not been very dependable in FCC service. We are using TDL (tunable diode laser) analyzers in our CCR (continuous catalyst regeneration) unit. Our experience with them in the CCR unit is extremely good. These are non-contact-type analyzers in which a small quantity of the sample enters from one side and exits from the other side. In these analyzers, the sample stream does not come in direct contact with any part of the analyzer, which greatly improves reliability. These TDL analyzers do not drift or require regular calibration checks.

FOSHEE [Shell Global Solutions (US)]

Sanjiv did a good job covering this question, but I will just add Shell’s experience. Shell has three sites with tunable diode laser analyzers in the flue gas line. Of these sites, one of the sites has tunable diode lasers as part of the safeguarding system for their ESP. This particular site does not have an expander. Another site has tunable diode lasers in place with the intention of using them for safeguarding their ESP, but they also have an expander and have noticed some signal irregularities when they put in walnut shells to clean the expander blades. So as a consequence, they now just use the tunable diode lasers for monitoring. A third site has tunable diode lasers in place for monitoring purposes only. This particular site does not have an ESP.

I will say that, in general, Shell’s overall experience with tunable diode lasers has been positive. They have a lot of benefits including their accuracy and reliability, combined with the benefit of requiring less maintenance. Some of the problems the tunable diode lasers have been the occurrences of laser transmittance issues due to particulates in the flue gas. This can usually be resolved with a proper purge rate. We are still searching for a solution to the irregular signal that occurs during the expander blade cleaning. High temperatures can sometimes cause problems for tunable diode lasers, but this can usually be solved with the heat shield. Also, vibration can sometimes be an issue, but not always with the tunable diode lasers.

EMERSON FRY (Delek Refining, Ltd.)

Most of the time when I see an application like this, it is typically on the flue gas line itself. On your diagram, it looks like you have a sample line coming off with it. So, is this another concern with condensation damaging the instrument?

SINGH (Indian Oil Corporation Limited)

I cannot say this because we are not using it for FCC at the moment. We are using this analyzer only for moisture analysis in the CCRU (continuous catalytic reforming unit) recycle gas. In this service, our experience has been very good.

SANJIV SINGH [Indian Oil Corp Ltd. (IOCL)]

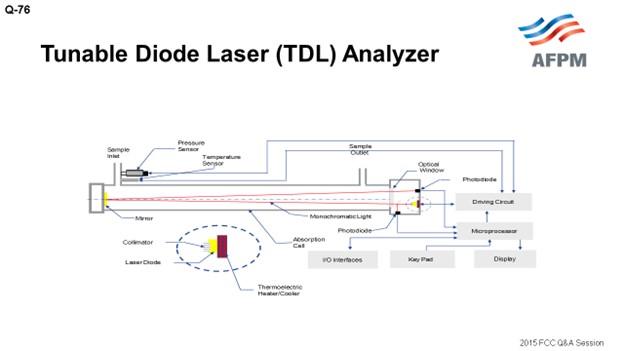

At present, we have no tunable diode laser (TDL) analyzers installed in our FCC units. Instead, there have been UV- (ultraviolet) or IR (infrared)-based analyzers in the flue gas circuit which have proven to be problematic and not very reliable. TDL is a single-line ‘monochromatic’ spectroscopy technique that offers various measurement advantages including highly stable calibration; continuous, fast in-situ measurement; and avoidance of cross-interferences from other gases. The TDL analyzer has improved technology with no drift and does not require calibration. The suppliers of the tunable diode laser flue gas analyzers claim the following benefits:

-

In-situ analysis without sample conditioning,

-

High dynamic range and accuracy,

-

Fast response (1 to 20 seconds),

-

High spectral resolution,

-

Process pressure/temp (up to 20 bar/1500°C),

-

Optical measurement (no sensor contacts with process), and

-

Practically calibration-free.

TDL analyzer vendors may be directly contacted to find out further details and reference units.

Though IOCL does not have direct experience with TDL analyzers in FCC, we are using the same in different applications; and so far, our experience has been very good. A TDL analyzer is being used for moisture measurement in a CRU unit, and the performance has been very satisfactory.

NIKOLAS LARSEN [Marathon Petroleum Company (MPC)]

MPC does not have any TDL analyzers in FCC flue gas service. However, we do have a few installed-on process heaters that are used to measure O2, and we are happy with their performance. In FCC flue gas service, MPC has one unit that utilizes an extractive system. The analyzer is the ABB AO2000 platform with a Magnos 106/206 Paramagnetic oxygen analyzer and an Uras 14/26 nondispersive infrared CO analyzer. This analyzer is mounted on the deck at the duct, so our sample line is very short: probably in the 10- to 20-foot range. Overall, we have been pleased with this setup.