Question 72: The FCC is LPG-constrained, and the refinery is octane short. What are your suggested options to increase FCC gasoline octane while minimizing any associated increase in LPG yield?

DE GRAAF (Johnson Matthey Process Technologies)

When the FCC is constrained in LPG and short on octane, the feed is one of the most important parameters for yields and quality of the yields. So, if you can, blend in more aromatic feeds. Or if you have feed pretreat, backing off from it will help improve your gasoline octane. However, this might come at the expense of higher sulfur in gasoline. If the FCC is LPG-constrained but not wet gas compression-constrained and allows for a small increase in dry gas, then consider increasing riser outlet temperature, which will help improve gasoline octane.

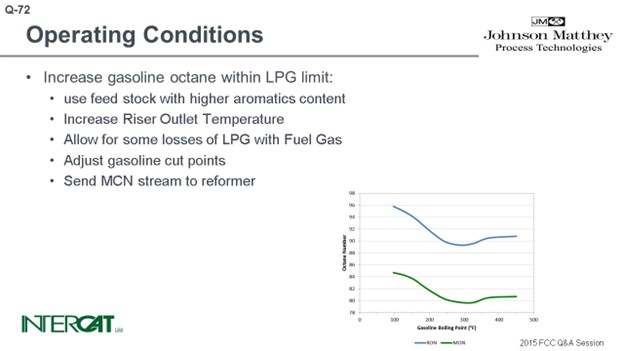

Other options include blending in high octane components, increasing Reid vapor pressure, and blending in ethanol, alkylate, or reformate. You could also change the cutpoint of the gasoline. Gasoline has a valley of octane, which is about mid-cracked naphtha. If you can reduce your gasoline cutpoint, if you have a low gasoline cutpoint, then you will typically increase your gasoline octane. Or if you have a high gasoline boiling endpoint, then if you increase your gasoline boiling point, you will increase your gasoline octane.

I have heard of another option used by one refiner who valued octane barrels so much that he allowed for some LPG losses to go with fuel gas. However, I am only aware of that one case. Another option is to cut out the MCN (medium cat naphtha) stream altogether and send it to a reformer.

When you optimize the amount of hydrogen transfer off of your catalyst, you can improve your octane. This requires reducing the rare earth on your zeolite and balance the amount of matrix versus zeolite activity, as matrix will not exhibit hydrogen transfer. So that will help improve your gasoline octane; and at the same time, a matrix catalyst will typically have a higher tendency towards mid-distillates and a lower tendency towards LPG. That will help you to increase conversion a bit further as well.

Increasing the catalyst activity typically helps to increase octane. Catalyst activity will increase delta coke and reduce cat circulation; and therewith, it will reduce hydrogen transfer. A last option can be the use of specialty ZSM-5 additives that do not really increase LPG but do increase the isomerization and, therewith, increase gasoline octane.

RICHARD RUSSEFF (CVR Energy, Inc.)

Bart covered the topic very well, and I have nothing further to add.

STUART FOSKETT (BASF Corporation)

When looking at catalyst optimization, our view is that this comes down to what gives the greatest increase in octane for the least delta in LPG yields. Very simply, of all the options that are available, reducing rare earth is the catalyst formulation change that will give you the best octane per delta LPG ratio. With a change to lower rare earth, it is necessary to increase fresh surface area in order to preserve activity and conversion. A lower zeolite-to-matrix ratio can help shift some of the LPG yield down to the light cycle oil (LCO) boiling range. The economics of a lower zeolite-to-matrix surface area needs to be considered very carefully. Normally, we find that making LCO from the reactor, as opposed to making it through cutpoint changes, is not generally very economic unless the value of diesel is significantly higher than gasoline. Also, in our view, ZSM-5 additives or catalyst that contains ZSM-5 crystal will give a higher LPG increase per unit of octane. We see that as a less preferable solution.

WARREN LETZSCH (Technip USA)

I presume that the ZSM-5 additives would be those with a very high silica-to-alumina ratio: probably 200:1 or higher. It would be an isomerization catalyst, not a cracking catalyst. I would really look at reducing the unit cell size or catalyst being used. While taking some rare earth out does that to some extent, it is the fresh catalyst unit cell size that can have an impact here. I would want to hold catalyst activity up because I do not want to lose conversion; but I might even go a little higher, and then I will be able to drop reactor temperature to hold conversion. So, if I could do it through a higher-octane type of catalyst, you might also consider lowering the sodium in the zeolite; because again, that will help raise the octane. You just have to look at your starting point and the type of catalyst being used.

KENNETH BRUNO (Albemarle Corporation)

Albemarle offers a catalyst solution beyond what has been discussed so far. Particularly, we have a very successful ACTION catalyst family that has been used in over 10 units. It has a novel zeolite technology which maximizes octane gain per gasoline loss. Moreover, it is selective towards butylene which is, of course, very valuable for your alkylation unit. We have provided a more detailed answer in the Answer Book, so I encourage you to review that information.

ROBERT (BOB) RILEY, III (Grace Catalysts Technologies)

One other option available that you may not immediately think of is to look at the use of a catalyst or additive to reduce gasoline sulfur, if you are losing octane in the post-treater. Several refiners have been reviewing this option over the last year or two. It can help preserve a lot of octanes as you come up on Tier 3 implementation.

KEVIN PROOPS (Koch Industries, Inc.)

I am not selling any catalysts or additives. [Laughter] The diesel (650°F minus) in the FCC feed will yield a lot of LPG. This question states that the LPG system is constrained. If you can make distillate instead of putting it in at the cat cracker, you might open up enough flexibility to play games with the riser temperature and the catalyst formulation.

BART DE GRAAF (Johnson Matthey Process Technologies)

When the FCC is LPG-constrained and the refinery is octane-short, there are various options to increase FCC gasoline octane without substantial increase in LPG. One of the most influential parameters is the feed to the FCCU. Feed containing more aromatic components (lower API) will yield typically higher-octane gasoline (at same conversion). When a feed hydrotreater is present, limiting the severity of the pretreatment will help conserve some gasoline octane as well (though this might come at the expense of gasoline sulfur). Streams with higher aromaticity usually have higher octane sensitivity octane sensitivity. FCC gasoline and reformate have high octane sensitivity, while alkylate has very low octane sensitivity. If gasoline has more isoparaffins (and less aromatics), it will exhibit lower octane sensitivity.

Secondly, operating conditions can help improve gasoline octane. Octane is very dependent on riser outlet temperature. Higher riser outlet will increase octanes (typically +1 RON, +0.6 MON/20°F). Increasing conversion always improves gasoline octanes, but it also increases LPG yields. Gasoline octane depends on the cutpoints. For gasoline with low final cutpoint (310°F or below), reducing the gasoline cutpoint will improve gasoline octanes as medium cracked naphtha (MCN) has a relative low octane value. For gasolines with high gasoline cutpoints (350°F or higher), increasing gasoline cutpoint will help improve gasoline octane as the higher boiling gasoline components have typically higher octanes. As the MCN stream has relatively low octane, an alternative approach is to cut it and send it to a reformer. If there is room, increasing Reid vapor pressure of the gasoline fraction will have a beneficial effect as well on gasoline octanes. From the operational point of view, a less conventional approach is to increase conversion and LPG and allow for some losses of LPG with fuel gas.

A third option is to optimize the catalyst. Octane improves when hydrogen transfer over the base catalyst is reduced. Therefore, the following must be considered:

-

Optimization of rare earth on USY (ultra-stabilized Y): Lower rare earth will yield lower hydrogen transfer and better octane

-

Balancing activity from zeolite and matrix: Matrix does not exhibit hydrogen transfer; more matrix activity reduces hydrogen transfer. A second benefit is that matrix catalysts have a higher selectivity towards mid-distillates, which reduces LPG yields.

-

Improvement of Gasoline Octane: Higher catalyst activity improves gasoline octane as well. Various catalyst vendors offer specialty ZSM-5 additives that increase octane at a minimal increase in LPG.

Each of the options above, or combinations thereof, can help improve gasoline octane. The most efficient solutions are unit specific as each unit will be maximized against its own set of operational limits.

RYAN NICKELL (Albemarle Corporation)

Combining operational and catalyst changes are an excellent solution for a refiner needing increased octane under an LPG constraint. Operationally, the riser temperature can be lowered to immediately reduce dry gas and LPG. The associated drop in conversion can be countered with a new catalyst, such as Albemarle’s ACTION. ACTION contains a high matrix content and will crack bottoms to valuable distillate under the lower riser temperature. The matrix is substantially resistant to iron, calcium, and other metals. ACTION catalyst contains ADZT-100, a novel zeolite technology that promotes isomerization reactions which improve octane of the FCC naphtha. This technology furthermore shifts the composition of the LPG towards C4 olefins which can, of course, be fed to an alkylation unit for further production of high-octane gasoline blend stock. The benefits of ACTION have been proven in over 10 FCC units.