Question 70: How do you monitor coke drum cutting water for fines content (test methods, frequency, time in cycle) and what is your trigger level for action to reduce fines content?

Rajkumar Ghosh (Indian Oil Corporation)

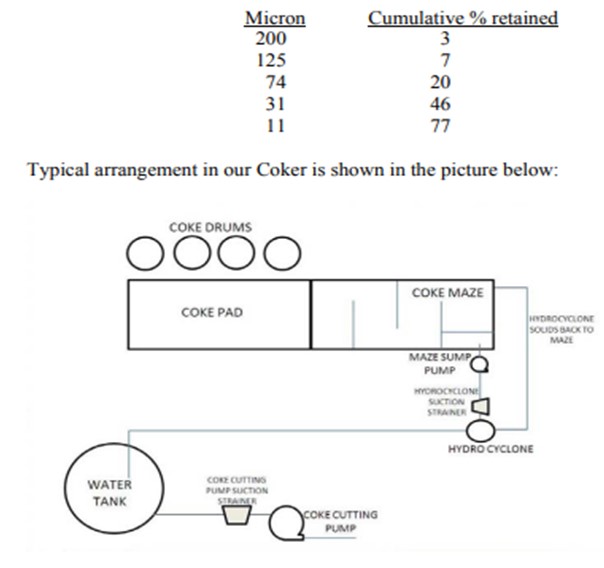

There are different methods to separate the fines in cutting water. In our latest Cokers, we have hydrocyclones, provided at the discharge of the reuse water pumps. The older cokers deploy clarifier.

The water reuse system consists of a settling maze and a vertical pump to pump the water back to the coke cutting water tank after separating the coke fines by passing it through hydrocyclone. The settling maze consists of 4 partitioned chambers, with water cascading from one chamber to the other, thereby effecting coke fines settling at stages. The coke cutting pumps typically take their suction from the middle of the water tank so that carried over coke fines settle at the tanks bottom. The hydrocyclone consists of 42 nos. of individual ceramic body cyclones, bundled in a cylindrical shell. It is designed to remove 80% of influent coke fines. The coke fines separated as hydrocyclone underflow, move back into the settling maze, while the clear water comes out as hydrocyclone overflow. In our case, the hydrocyclone is designed for the following influent conditions:

− Flow rate: 250 m3/hr

− Solids: 0.04-3.0 wt%

− Particle size distribution

The monitoring of water quality is necessary to prevent damages in the coke cutting nozzle and coke cutting pump impeller. We adopt the following monitoring mechanism for ensuring the coke cutting water quality:

a. The coke cutting pump has a suction basket strainer of 80 mesh size. The strainer is taken up for cleaning when ΔP across the strainer becomes 0.25 Kg/cm2. Under normal situations, the strainer is required to be cleaned once a week. Underperformance of hydrocyclone is reflected in frequent clean-up requirement of the strainer. In such cases, the hydrocyclone is opened up and the clogged cyclones are cleaned. Typically, the hydrocyclone is cleaned after every 4 months.

b. Based on our experience of occasional clogging of hydrocyclone due to excessive fines generation, we had installed a strainer at the upstream of hydrocyclone. The frequency of strainer cleaning gives us a fair indication of the extent of fines generation in the coke cutting process and thereby corrective action in the process parameters.

c. The coke fines get separated at stages in successive chambers of the maze. During the end of the cutting cycle, we collect water sample from the last chamber of the maze and allow settling for a while. By visual comparison with the earlier samples, we try to ascertain whether excess fines are getting generated in the process. Coke fines are removed from the maze by the bridge crane. Generally, once a day cleanup is adequate.

d. The residual coke fines which pass through the hydrocyclone tend to settle in the water tank. The tank bottoms are drained into the settling maze after each cutting cycle to remove the fines building up at the tank bottom.

e. Despite the actions as above, if the coke cutting pump suction strainer requires frequent cleaning, the water tank content is partially replaced with fresh water.

f. And finally, settling maze and the water tank are completely taken up for cleaning during unit turnarounds.

Although the water sample from the coke cutting pump suction can be monitored for coke fines content by periodical sampling and its’ lab analysis by filtration method, in practice it is quite infrequent in the field. However, the safeguards and practices, as explained above have been found to be effective and we have not experienced any deterioration in the coke cutting pump and cutting tool in the last 5 years operation of this particular refinery.