Question 7: How is propane content in the refrigeration loop optimized against the compressor capacity to minimize contractor temperature? Do you have a good process model to predict the optimum propane content?

KLEISS (Valero Energy Corporation)

There is an optimum propane concentration in the refrigerant that will allow the alkylation unit to operate at a maximum alkylate throughput when the unit is up against limitations of both the compressor and the reaction zone heat removal capability. That optimum concentration of propane will vary from unit to unit and can be different seasonally. It can also be different from night to day or if exchangers are fouled, etc.

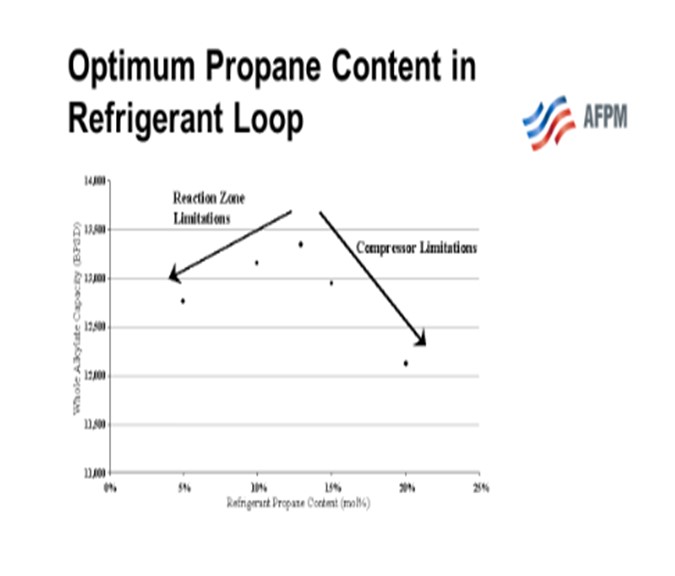

We received some information from STRATCO® where they reported that a Caribbean refiner, who was limited by reaction temperature, plotted daily alkylate production rate versus refrigerant propane content over a long period of time. Since the ambient temperature was relatively constant, the refiner was able to produce a scatter chart,similar to the one below.The chart shows that there was,indeed,an optimum propane amount in the refrigeration loop.STRATCO® has no model to predict this optimum. Producing a plot similar to the one below is the best way to try to optimize the propane content.

The Valero units typically operate at capacity with butylene feed, leaving limited room for feeding propylene. Therefore, there is not a lot of propane to remove from the system. The units operate with propane content in the refrigerant loop in similar ranges as those shown on the next chart. Valero has no process model to arrive at optimum propane content.