Question 68: Do you see any benefit in continuing to steam strip crude tower distillate cuts since these side streams require further processing in down stream hydrotreaters?

Jim Johnson (Marathon Petroleum)

We have observed definite benefits to steam stripping the distillate cuts and have been working to determine whether the benefit is worth the cost.The main purpose for distillate side strippers is to control product flash with a secondary purpose of lifting lighter material and affecting the product cuts. If the kerosene and diesel streams go directly to hydrotreaters and there is no concern with flash in an intermediate storage tank, the flash can be effectively controlled at the hydrotreater stripper. However, it comes at a cost also.

In looking at steam stripping the diesel cut, the target should be to lift just enough of the lightest naphtha range material to reach the minimum flash target. Incremental kerosene production is normally sold as diesel fuel, so there is not an incentive to lift any more than is necessary. One must determine how much naphtha is required to be lifted to control flash and if it’s not lifted in the side stripper then it will be processed through the diesel hydrotreater and lifted in the product stripper. We have an example at one of our refineries with two crude units where one of the diesel side strippers has been operated without stripping steam due to a mechanical problem with the stripper while the other crude unit diesel stripper is operated normally. We have observed a very small difference in the flash and front end of the distillation between the two streams, bringing into question the value of steam stripping the diesel draw. And a likely more important variable beyond the utility cost comparison is the value of distillate hydrotreating capacity to the refinery.

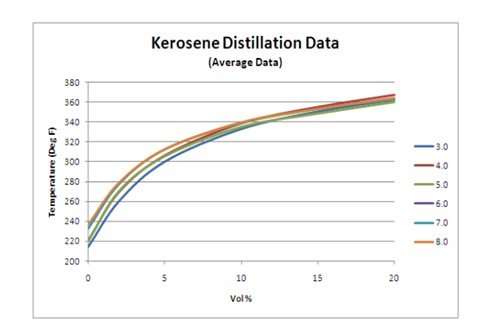

Side stripping kerosene is slightly more complex in that the stripping steam not only controls the flash but is effective in assisting the distillation between naphtha and kerosene. We recently conducted a test at one of our refineries varying the stripping steam ratio from 3 #/bbl to 8 #/bbl in an effort to quantify this benefit and compare the utility costs. The following graph illustrates the effect of increased stripping steam on the kerosene distillation, as observed during the test run.

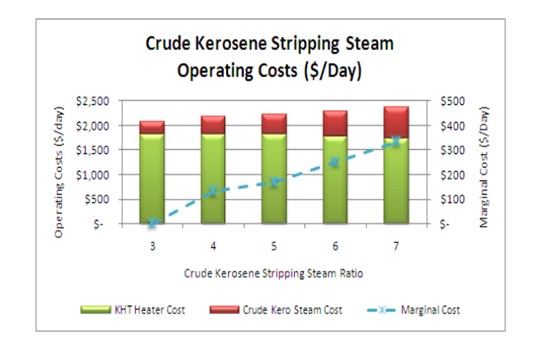

At this refinery the kerosene stripper, OH liquid is routed back to the crude tower; thus, the utility cost of the stripping steam can be compared directly with the incremental cost of processing the naphtha through the hydrotreater furnace. It was determined that the cost of steam is more than the cost of incremental heater firing.

This comparison is limited to the utility costs involved. Product economics may also factor into this evaluation.

At another of our refineries the naphtha endpoint was being targeted very low resulting in an excessive load being placed on the kerosene hydrotreater. The hydrotreater charge heater was pushed to maximum firing rate and the product stripper was pushed beyond design velocities resulting in a failure due to erosion/corrosion. Plus, at this refinery the kerosene hydrotreater stripper OH liquid is routed to the diesel hydrotreater, then back to the crude unit, thus incurring the cost of heater firing twice. More importantly the naphtha that recycled back to the crude unit utilized valuable capacity in both the kerosene and diesel hydrotreaters.

Each refinery should determine their cost/benefit of side stripping the distillate streams, as the answer will likely be different from one refinery to the next.

Eric Thraen (Flint Hills Resources)

The benefits of side-stripping crude tower side-cuts depend on whether the crude unit or the downstream processing unit is more constrained. Downstream units include the product desulfurizing units as well as the sour water strippers. Maintaining at least a minimum stripping steam rate in the side-cut strippers helps to ensure the downstream hydrotreater feed drum does not see excessive light oil in that unit's feed drum. For example, too much heavy naphtha in a Jet/#1or Diesel/#2 hydrotreater feed drum can cause that unit’s feed drum offgas pressure control valve to open if the feed drum runs hot due to multiple feed sources. Generally, the majority of the light product recovery stripping benefit is provided by a small increment of stripping steam, with diminishing returns for stripping steam above that minimum. In addition to the feed drum pressure/offgas issue, depending on the refinery’s configuration, multiple units recycle can result if light oil is not stripped right the first time. For example, excessive naphtha in a Jet or #2 Diesel side-draw will be stripped overhead at the downstream DHT Stripper. If the DHT Stripper overhead gasoline is routed to a Sat Gas Plant this will load up that GRU, whose product may then be re-hydrotreated at a naphtha desulfurizer before ultimately finding its way to finished product tankage. The recycle caused by poor stripping consumes capacity at multiple processing units.