Question 67: With double-fired heaters, how long do you run between decokes (mechanical or steam-air)? What is your steam spalling interval? How much velocity steam do you maintain?

Rajkumar Ghosh (Indian Oil Corporation)

We have 8 operating Delayed Cokers across our Refineries. Of these, 2 have double fired heaters and others have conventional single fired heaters. With similar feed and Coker operating parameters, the double fired heaters are expected to have longer run length.

We get an average run length of ~12 months between decokes for one of our double fired heaters with on-line spalling of individual passes at an interval of 5-6 months. We process VR feed (CCR ~21 % wt; Sodium ~15 ppmw) with approx. 3%wt CLO and 12%-14 % recycle, and operating at 100% capacity level. We have also experienced a run length of about 2 years when the heater was operated with lower throughput and higher recycle (17-18 %). However, the coke deposit was very hard to remove by mechanical pigging and could only be removed by steam air decoking.

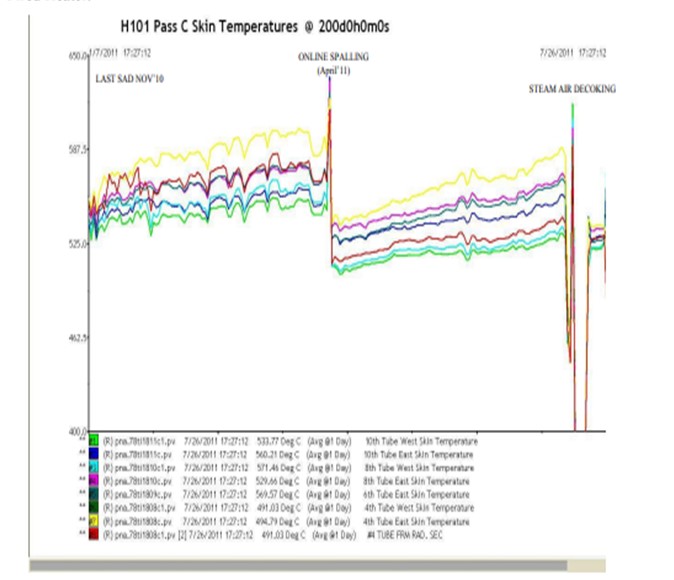

Tube metal temperature (TMT) and heater ΔP constitute the triggers for on-line spalling. In our case, with P-9 tube metallurgy, the trigger values are 614o C and 7 Kg/cm2 respectively. We always experience that the TMT limit triggers the requirement for on-line spalling, much before the ΔP occurrence. Between the SOR and EOR, the ΔP increase is limited to 1.5 Kg/cm2. One day average skin temperatures for over 200 days, is attached below for a typical pass in a Double Fired Heater.

It is important to mention that operational practices play a vital role in achieving longer run lengths of Coker Heaters and some of them are as under:

− Avoid interruptions which cause premature coking

− Feed quality, especially high Sodium and CCR aggravate coking

− Avoid any flame impingement on the heater tubes

− On-line monitoring of tube Skin Temperatures

− Keep the burner fuel pressure optimum

− Regular visual inspections

− Strict monitoring of Delta P across each pass

− Strict monitoring of velocity medium

Our Steam spalling interval is about 5-6 months. We undertake on-line spalling before the TMT reaches the threshold value of 614o C. In another upcoming Coker unit, skin temperature threshold value is 690o C and in this case steam spalling interval could be more than 6 months. Licenser does not recommend spall interval beyond 9 months as tube wall deposits become hardened and difficult to remove with subsequent spalling.

In all our 8 Cokers, we use Boiler Feed Water (BFW) as velocity medium, injected at the inlet of convection section, at the downstream of pass flow control valves. We maintain BFW quantity of 0.8-0.9 wt% on heater pass flow up to a maximum of 1% wt. At lower throughput, the velocity water is increased to approx. 1 wt%.

We have also used velocity steam in one of our Coker as a stop gap arrangement once for approx. 24 hrs when Boiler feed water was not available from upstream. No significant impact on delta P across the heater tubes or skin temperatures was observed after this operation.

Eberhard Lucke (Commonwealth E&C)

This question is lacking definition since it doesn’t define the severity of operation that the heater is required to perform in. I know of charge heaters in units with very high recycle ratios and very light residue feeds that can run up to 18-24 months between decoking. Other, more sever operations with ultra-low recycle and very heavy, aspaltenic residue feed show times between decoking that range between 3 months down to 6 weeks. This is independent from the type of decoking applied: pigging or steam-air decoking. These numbers are all based on no application of steam spalling. Steam spalling intervals may start at every 3-4 months, but will deteriorate with every application depending on how close the new SOR conditions are to the SOR conditions after a rigorous mechanical or thermal decoking. The minimum recommendation for velocity steam is 0.75 wt% of heater charge rate, but with heavier oil being processed and unit operations becoming more severe, values of 1 to 1.5 wt% of heater charge rate are becoming more typical.