Question 6: What are your typical disposal options for solid phosphoric acid (SPA) catalyst from a catalytic polymerization unit? Are you employing any innovative methods?

KINDERMAN (Clariant Corporation)

We normally see disposal to a landfill, assuming the catalyst is hydrocarbon-free and neutralized. Because of that phosphoric acid, the SPA catalyst can be used as a fertilizer. It must be hydrocarbon-free and other impurity-free and then treated before it can be used as a fertilizer. It does not contain any nitrogen, so there is a prep step before it can be utilized as a fertilizer. Spent catalyst treatment, like I said, adds nitrogen, but it must basically be impurity-free. There are no other promoters or anything else that can be added in the fertilizer step.

We are investigating the use of fertilizers or spent SPA catalyst with fertilizers, and we are working with a couple of companies to see if this is feasible. It is a small dollar amount to build a typical fertilizer plant, so it is hard to get them motivated other than to add the green symbol you will get for utilizing the fertilizer.

SUGG (Honeywell UOP)

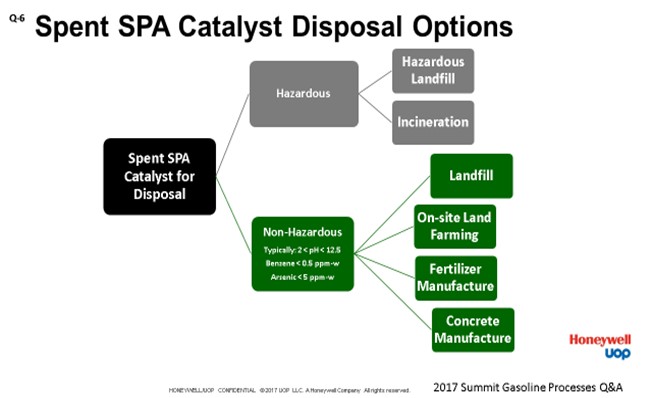

UOP prepared this slide based on the different classifications of the spent SPA catalyst. If it is hazardous, there are special hazardous landfills for this material. Incineration is another option.

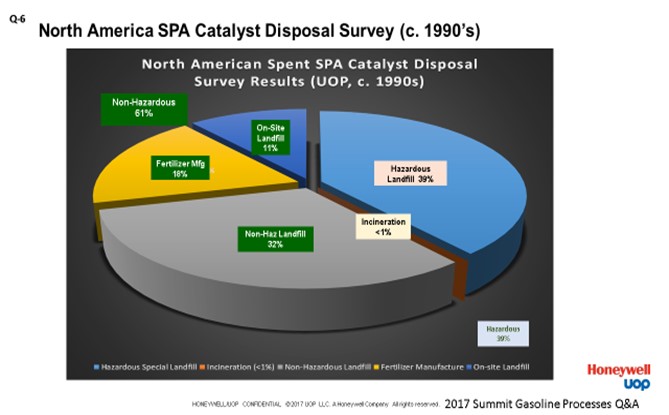

If is non-hazardous and meets the specifications of moderate or controlled pH (benzene less than 0.5 ppm and arsenic less than 5 ppm), then it can be disposed as non-hazardous. Like Bryan said, there are various options like landfill, onsite land farming fertilizer, or even concrete manufacture. A few years ago, UOP surveyed our customers about how they dispose of this material. The next slide shows the percentages we received back when we did this survey. It is getting a little dated, but 61% of the material was disposed of as non-hazardous and 39% as hazardous. At the time of this survey, the practice of putting the spent SPA catalyst into concrete was just getting started, so there are no results for that option here. Also, the hazardous material tends to be from SPA catalyst used for cumene production because it is difficult to remove the benzene from the spent catalyst prior to disposal.

SHARON (Valero)

This question has already been well covered. We currently stabilize and landfill. On the slide, you can see the potential options that we are investigating. We have not had any luck with the agricultural usage yet, but we continue to consider that option.

MARTHA BUCHAN (Honeywell UOP)

Based on input from previous surveys and discussions with Honeywell UOP SPA customers, appropriate catalyst disposal methods are determined by the spent SPA catalyst’s classification, whether hazardous or non-hazardous. If hazardous, the options are hazardous landfill or incineration. If the spent SPA catalyst is defined as non-hazardous, there are several options: landfill, onsite land farming, concrete, or fertilizer manufacture.

A significant portion of spent SPA in the United States (U.S.) is disposed of in a non-hazardous landfill. The main issues pertaining to non-hazardous material regarding spent SPA are toxicity and corrosivity. As a liquid, the material must have a pH between 2.0 and 12.5. The spent catalyst must meet the benzene and arsenic specs of less than 0.5 ppmw and less than 5 ppmw, respectively. The key is to keep the material dry and/or neutralized (usually with lime, sodium carbonate, or neutralizing medium). The spent SPA material can become very corrosive if it comes into contact with free water; therefore, the proper facilities for liquid neutralization would be required.

Many years ago, UOP conducted a survey for SPA catalyst users in the U.S. and Canada. The following disposal methods were reported based on weight of material:

|

Hazardous Special Landfill |

39% |

|

Non-Hazardous Landfill |

32% |

|

Fertilizer Manufacture |

18% |

|

Onsite Landfill |

11% |

|

Incineration |

<1% |

The survey was completed prior to customers’ pursuing cement manufacture as a potential disposition for the spent SPA catalyst; so, while this is still expected to be a low percentage, it is not included in the table above. The results of the survey include motor fuel, cumene, and higher olefin-type operations. Although exact numbers are not available, a high percentage of the material going to hazardous special landfills comes from cumene units where benzene is used as the feed and difficult to remove to acceptable levels.

BRYAN KINDERMAN (Clariant Corporation)

Traditional disposal for SPA is taking it to a landfill, assuming that the catalyst is hydrocarbon-free and neutralized. Because of the phosphoric acid, SPA catalyst can be used as fertilizer. The catalyst must be hydrocarbon-free and devoid of other impurities and then treated before it can be used as a fertilizer. The catalyst does not contain nitrogen. There are ongoing investigations about reclaiming the phosphorus as phosphoric acid for other use.