Question 47: How does a recycle compressor driver type (steam turbine versus electric motor) affect compressor availability in hydroprocessing units? How reliable are variable speed drives?

MORELAND (Valero Energy Corporation)

Gordon, I have 47 slides on this one. Actually, just kidding! I have no slides on this one. [Laughter]

Our experience at Valero has been that turbines are more reliable than electric motors. For electric motors, the failures are not caused by the motor itself, but rather by the availability of electric power. Power failures tend to be the most common concern. Turbines are also available to run in variable speeds, but we usually run them at a set speed with spillback instead. We give up some energy efficiency but gain on operating reliability.

As far as electric motors for compressor drivers, we do not use those for recycle gas compressors due to a power failure scenario. However, we commonly use electric drivers for makeup compressors. However, with makeup compressors, there is typically a sparing philosophy: either two times 100 or three times 50% configurations.

As far as variable speed for electric motors, we have very limited experience. Our refinery in Pembroke in the U.K. (United Kingdom) does use that in one of their DHTs with particularly good experience. However, we have a variable speed driver at the McKee Refinery where we have bypassed that variable speed driver. We find them more common in Europe due to the drive for higher energy efficiencies.

McARTHUR (Phillips 66)

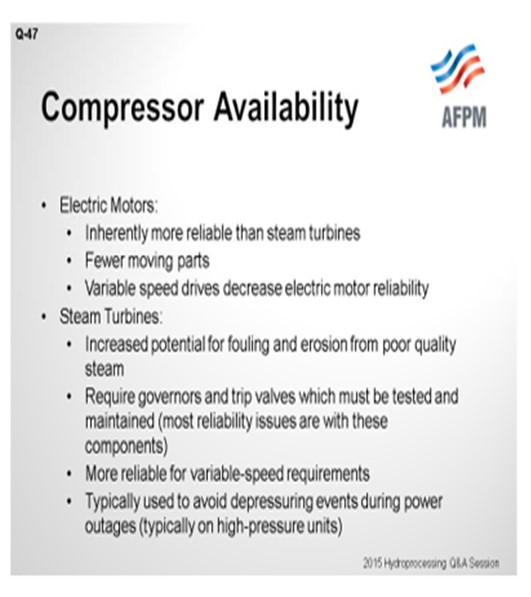

So, power failures aside, electronic motors are inherently more reliable than steam turbines, and it is primarily because electric motors have fewer moving parts. Introducing a variable speed electric motor makes that system more unreliable, in our findings, and we typically do not use variable speed drives on our primary equipment for hydroprocessing units.

Steam turbines have potential fouling and erosion associated with poor quality steam. Additionally, steam turbines require governors and trip valves, which have to be tested and maintained. This equipment is where we have most of the reliability problems with turbines. However, we find turbines to be great for variable speed requirements, and we have made extensive use of steam turbine drivers to avoid depressuring events during power upsets, which Andy mentioned. Use of steam drivers is particularly important for the high pressure hydroprocessing units.