Question 46: What are the mechanical integrity implications for reactor effluent air REAC) after experiencing high-temperature exposure during emergency shutdowns or trips?

EPSTEIN [Flint Hills Resources, LP (FHR)]

During emergency feed removal or partial feed loss of a hydroprocessing unit, the loss of feed oil as a heat sink through the feed/effluent exchangers can elevate temperatures downstream. Expected temperatures can be estimated through process modelling of normal maximum reactor effluent flow continuing at maximum reactor outlet temperature without feed flow through the reactor effluent cooling train. Some systems at Flint Hills Resources have limited the reactor outlet’s normal maximum temperature, based on results of this modelling, to maintain temperatures within all design limits downstream. On most units, SIL-rated interlocks will trip the fuel gas flow to the charge heater in case of loss of oil. Even recycle-hydrogen-only heaters have a trip to prevent contribution to the heat wave.

Damage mechanisms for reactor effluent air coolers (REAC) with sudden elevated temperature include high-temperature hydrogen attack, thermal expansion/fatigue, and other longer-term corrosion mechanisms.

In case of an emergency involving a reactor temperature excursion, an emergency depressurization would be either automatically or manually initiated. This depressurization would both increase the permissible piping operating temperature (per ASME 16.5) and decrease the system hydrogen partial pressure. For a short-duration heat wave, regardless of the system pressure, degradation due to high-temperature hydrogen attack (HTHA) is not expected to occur. The heat wave will only last until the hot oil is pushed from the system. SIL-rated trips of the charge heater should have coincided with the feed removal, further cooling the reactor effluent. Leak checks would be conducted as part of the normal restart procedure during the nitrogen pressure/depressure steps prior to the introduction of hydrogen. On the REAC, the risk of tube-to-tubesheet joint leakage is present from thermal expansion. In most cases, these joints are seal-welded, and the probability of failure is low. If the unit passed the leak checks, the equipment would be restarted.

PEDERSEN (UOP LLC, A Honeywell Company)

The following comments are made from the perspective of killed carbon steel reactor effluent air coolers and/or piping. When a reactor effluent air cooler (REAC) experiences high temperature during an emergency trip or shutdown, the carbon steel can be exposed to conditions favorable to high-temperature hydrogen attack. These conditions do not exist at normal reactor effluent air cooler operating temperatures.

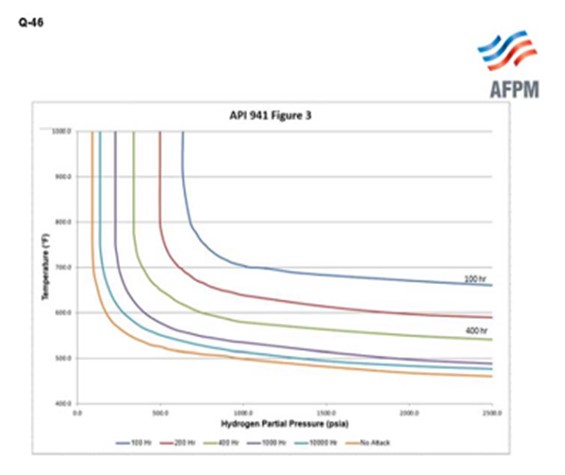

High temperature hydrogen attack damage is cumulative, not instantaneous, and is difficult to detect on inspection until it reaches the latter stages of damage. UOP has conducted a series of surveys and investigations on incidents from various customers. We have found that during a loss of feed case, for example, REACs cool down to temperatures below the killed carbon steel curve within about an hour. We also estimated that over the life of the unit, there would never be more than, let’s say, a wild number 400 of these incidents, which led us to use the 400-hour incubation curve from Figure 3 of API 941, shown here. The green line in the center is the 400-hour curve.

Regarding runaway temperature reactions in the reactor, by the time the excursion reaches the REAC, both the temperature and the pressure should be much lower than when the incident initiated. Temperatures should not be a major threat as long as the temperature runaway incidents do not occur on a regular basis. If the unit experiences frequent temperature runaways, we recommend a Fitness for Service evaluation.

From a physical perspective, Paul already discussed the potential for thermal stress. As hotter than normal temperatures enter the REAC, the first-pass tubes will be heated up quickly; the other tubes will heat up more slowly. Consequently, the first-pass tubes will thermally expand more than the second-pass tubes. This thermal stress can result in bowing of the tubes; and in extreme cases, tubes may pull out of tube sheet. It is assumed that operational temperature excursions are considered in selection of fins for the REAC so that the fins remain firmly attached to the tubes in spite of high temperatures.

One last point: If the reactor effluent air cooler uses induced draft fans, the potentially higher temperatures need to be used to evaluate the materials of construction. For example, fiberglass fan blades may not be acceptable for this application.