Question 43: What are your economic and operational reliability implications of increasing cycles of concentration in your cooling tower?

LANCE COX (NALCO)

The benefits of increasing the cycles of an open-recirculating cooling tower include cost reductions for:

-

Water - Purchased and Waste treatment.

-

Chemical Treatment – Raw Water Clarification and Waste Treatment

-

Electrical Costs – Pump Requirements

-

Capital Cost Deferral – Plant Capacity Expansion via Utilities Optimization vs. Replacement

-

Plant Infrastructure Spending – Minimize Maintenance Spend on Existing Caused by Capacity Limitations or Reliability Issues (i.e., Piping with Reduced Volumetric Capacity)

Operationally, especially as production units are debottlenecked over time, increasing tower cycles could facilitate the ability to utilize existing Utilities Infrastructure. This minimizes the need to undergo a disruptive engineering and installation processes should unit capacity enhancement projects be identified. This also aids in speeding those projects to fruition.

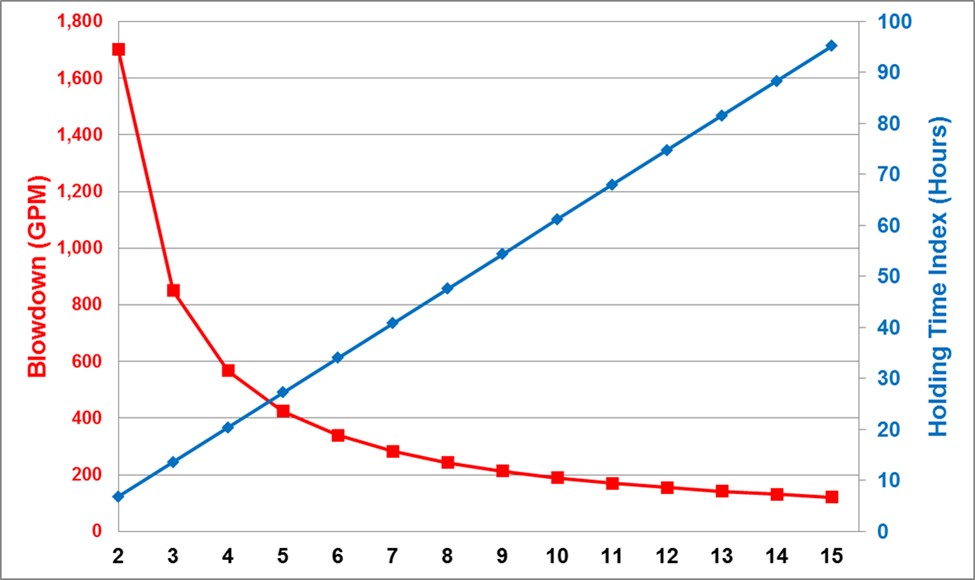

Certain reliability implications will be experienced to varying degrees. Increased cycles will impact the Water Quality, which can impact each heat exchanger in the circuit. A higher ionic species in the water will need to be evaluated from various aspects, including corrosivity, scaling and emissions (Air - PM10/2.5 and Receiving Bay TDS Regulations). The advent of enhanced treatment chemistries has broadened the acceptable operating window of these systems, while preserving performance capabilities. That said, the impact upon emissions should always be observed along with the diminishing returns as cycles increase. The non-linear characteristic of cycles vs. blowdown rate shows the sharp decline as cycles increase beyond the 5 to 8 level, while the Holding Time Index (HTI) increases steadily. (See Figure) HTI is one stress which becomes evident with respect to the treatment chemistries and crystal development characteristics, potentially leading to mineral scale deposition. The percentage of make-up water flow blown down from the cooling tower can be calculated by taking inverse of the cycles level. This states that the % of the tower make-up flow blown down will DECREASE from 20% (5 Cycles) to 10% (10 Cycles).

Reliability is only partially determined by Water Quality. The design characteristics of the exchanger circuit and individual exchangers are critical. Stress factor impact on heat exchange surfaces, such as Skin Temperature, Flow Velocity and Heat Flux will be exacerbated by a change in Water Quality. Each exchanger should be evaluated with respect to its design and how the water is changing. This analysis could require adjusted control strategies, including different limits, chemical treatment products, and possibly tighter control expectations. A thorough analysis of the various Mechanical, Operational and Chemical aspects of the system should be included in the decision to increase cooling tower cycles.