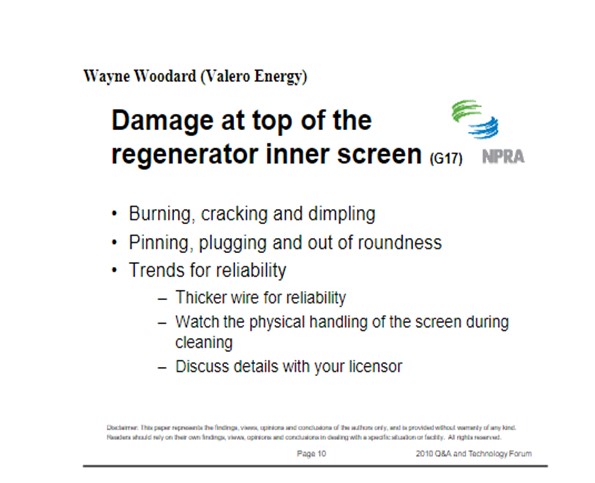

Question 42: In your experience, what are the typical causes of damage to the top of the regenerator inner screen?

John Clower (Chevron)

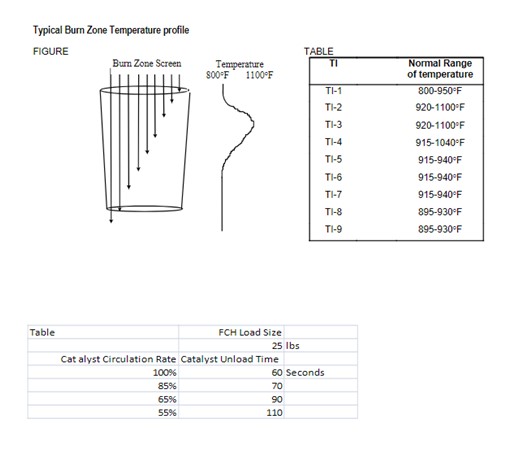

The typical cause for damage in the top 2-3 ft of inner screen is metal fatigue due to thermal cycling.This is common to all CCR designs, but more critical in early pressurized designs. Catalyst entering the regenerator from the vessel above is relatively cool, from the catalyst lift and elutriation. The cold catalyst enters the regenerator and the regeneration gas at the top of the screen will cool as it passes through this top section of catalyst, then in turn the gas will cool the inner screen.

As the carbon burn begins, catalyst temperature will increase thereby causing the inner screen temperature to rise. Each time catalyst cycles, a thermal cycle at the top of the regenerator inner screen will occur.

The thermal cycle can also occur if oxygen control is fluctuating significantly but in this case the damage will not be confined to the top section of inner screen.

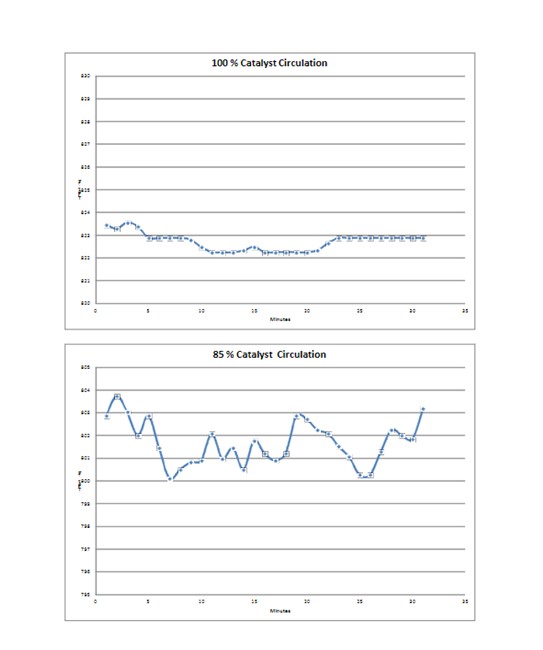

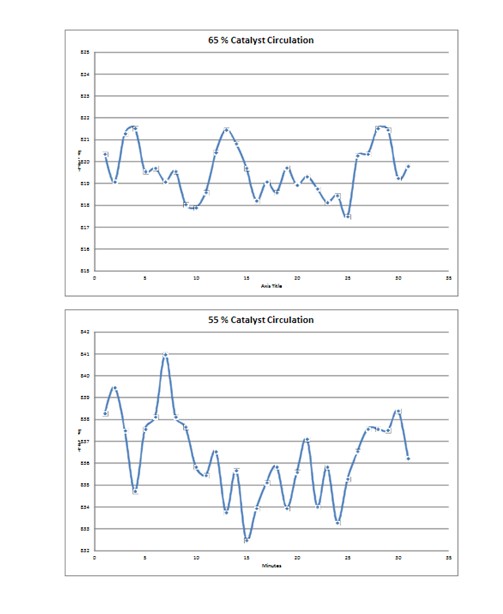

Catalyst circulation rate plays a part in the amplitude of the temperature cycle at the top of the inner screen. Lower catalyst circulation rates lead to larger cycles and increased fatigue. The same is true for shutdowns that occur during normal operation at any catalyst circulation rate.

The increased amplitude of the thermal cycle at lower rates can be problematic for CCR units operating at lower reactor severity. Consideration should be given to metal fatigue when determining how to operate in a low coke make regime.