Question 41: Can you comment on the use of liquid and/or vaporized naphtha as feed and/or fuel to a hydrogen generation unit?

Ken Chlapik (Johnson Matthey Process Technologies)

Johnson Matthey has vast experience in direct reforming of naphtha feedstocks in SMR’s for hydrogen production. The naphtha needs to be vaporized to be processed in the SMR based hydrogen plant. It takes less heat load to reform a mole of naphtha as compared to natural gas, but more COx will be produced, and the carbon formation potential is higher in naphtha which can have an average carbon content of C6 and a tail to C20. Because of this, each case needs to be evaluated for changes in feedstock purification, operating conditions such as S/C, reformer catalyst loading, the water gas shift section’s ability to process the higher CO conversion demand, and PSA recovery or CO2 purification issues to hydrogen purity.

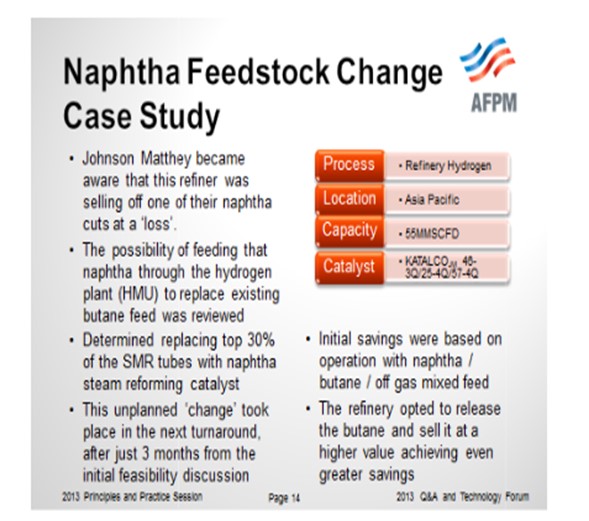

At last year’s 2013 AFPM Q&A’s Hydroprocessing Principles and Practices session on “Benefiting from Emerging Hydrogen Sources” a case study was presented on changing to a naphtha feedstock as shown below. The case study highlighted a low or no value naphtha cut being available in the refinery. Johnson Matthey evaluated replacing the existing butane feed which had a much higher market value than the naphtha. The plant was able to put the changes in place after 3 months and pay back the costs of this change in months. As availability of naphtha grows from increased natural gas production and particularly in refiners that are more centrally located in North America, direct naphtha reforming in SMR based hydrogen plants presents an option to process this naphtha.

.

Gopi Sivasubramanian (Foster Wheeler USA Corporation)

Foster Wheeler USA has designed plants with liquid naphtha feed stocks. The naphtha feed is vaporized. Besides the design issues that are to be accounted for the feed section, there are other areas of the plant that would require some modifications to handle.

Use of naphtha as fuel requires project/ site specific analysis with respect to safety/ firebox operations, design of fuel conditioning skid and burner system.

Pat Bernhagen (Foster Wheeler USA Corporation)

The Terrace Wall Reformer has been used for years in services with liquid or naphtha feeds using the split load of catalyst. The low flux of the inlet region of the cat tube and the countercurrent process to flue gas flow provide the ability to handle these feeds.