Question 40: What has been your experience regarding time required for hydrocracking operations to recover from temporary poisoning by organic nitrogen in the feed? What operational changes can be made to reduce the chance of permanent deactivation?

TEMME (Albemarle Corporation)

It can be a short duration, one to two days, or potentially longer, 21 to 30 days, depending on the response to the events and dependent upon the amount of higher severity feed, higher nitrogen, and higher aromatic content feed. It could be a shorter duration if quickly caught and corrected. If there is a feed endpoint excursion that just goes for four hours and affects the first two beds, then there is the potential for quicker recovery. One way to deal with it and get a quicker recovery is if the offending feed is rerouted back to the crude unit and reprocessed, if possible. It can be definitely a longer period if the offending feed process affects the whole catalyst loading.

Some potential operational changes include rerouting the off-spec feed or maybe reducing the amount of off-spec feed through flushing. Another option is dilution with easier feed, a lower aromatic content, and lower nitrogen-content feed. We generally recommend not chasing the product specs, if possible. The problem with chasing product specs with significantly higher reactor temperatures is that it can accelerate coking deactivation. And as always, if you can maximize treat gas rates that will be helpful.

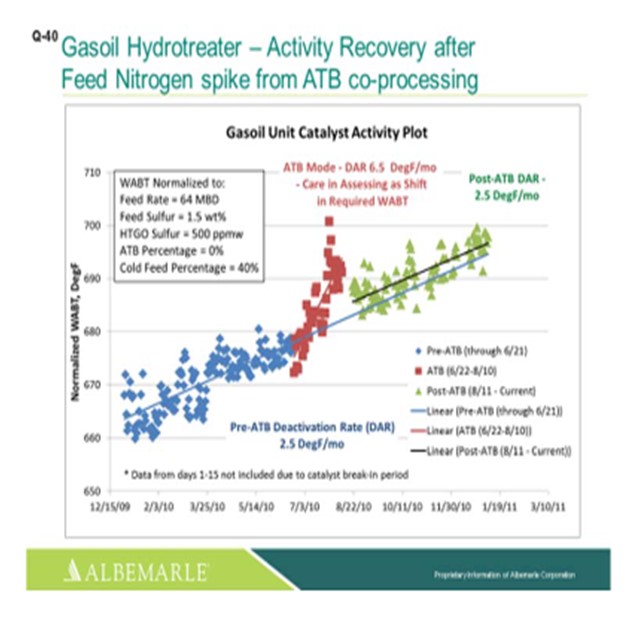

This slide shows an actual gas oil hydrotreater operation or the hydrocracker pretreat where this gas oil unit, by choice, took some opportunity to co-process some ATB (atmospheric tower bottoms) feeds at about 15 to 20% of the feed. In the upper left corner, you can see the unit conditions. Initially, the unit was a very stable operation before the ATB co-processing period with 2.5°F per-month deactivation rate. Then with the ATB co-processing, there was a ramp-up in the deactivation rate. Now, I would say that there needs to be some care when assessing the deactivation rate as there will be a shift in the required reactor temperatures/WABT. But after the ATBs were removed, there was recovery. The deactivation rate got back to a 2.5°F per-month deactivation rate, but there was 5 to 6°F of permanent activity loss.

MORELAND (Valero Energy Corporation)

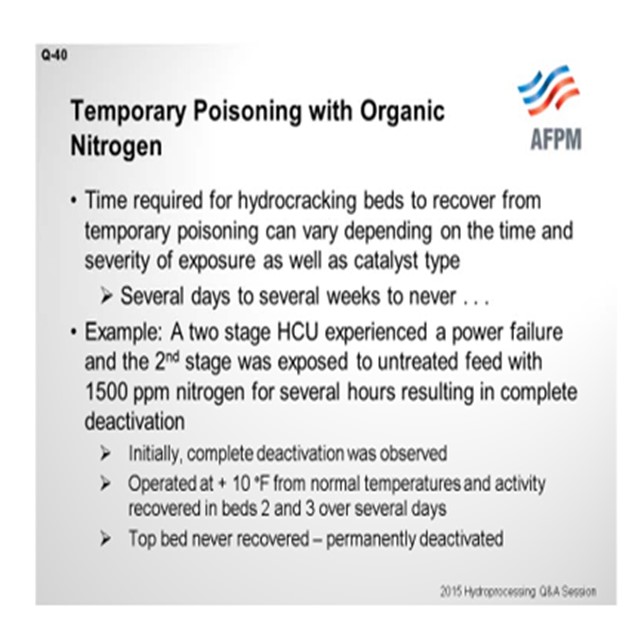

Recovery for hydrocracking beds from temporary poisoning can vary depending on the time and severity of the exposure and the catalyst type. Several days is fairly common. It could be longer than that, or it could never recover. This is an example that we discussed a little earlier: a two-stage hydrocracker that sent raw feed to the second-stage. In this case, we saw complete disappearance of the exotherm initially. After that, we did operate at 10°F higher than normal operation and saw recovery of activity in Beds 2 and 3 over a period of several days. However, Bed 1 never recovered for that cycle.

So as a subject matter expert, my recommendations to our engineers are that if it is a smaller nitrogen excursion for a shorter period of time, we would expect a recovery of activity. Our recommendation is to avoid increasing much above normal operating temperature – again, 5 to 10°F above – due to the possibility of a temperature excursion. Once that nitrogen desorbs off the catalyst, the exotherms could increase. We want to avoid a temperature excursion situation. That will manifest itself as lowered conversion across the hydrocracker. Monitor it closely; and when signs of recovery are evident, reduce the bed inlet temperatures to prevent a temperature runaway.

PEDERSEN (UOP LLC, A Honeywell Company)

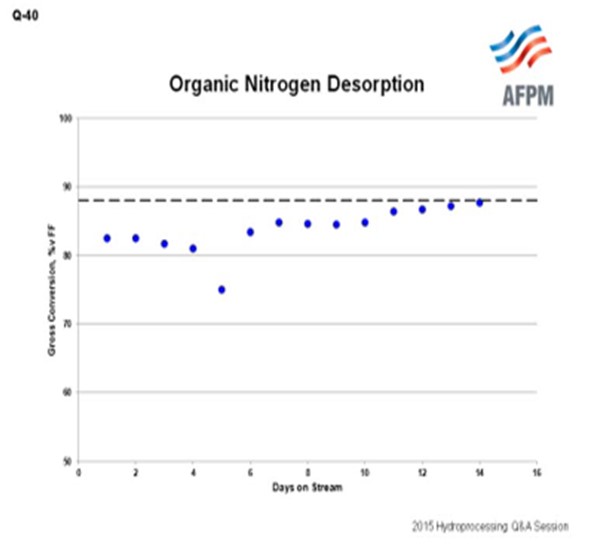

The following chart shows an example of the effect of organic nitrogen inhibition at start-of-run. As seen in this chart (achievable conversion versus days on stream), 15 days of operation were necessary to bounce back from the inhibition at start-of-run and achieve target conversion. Typically, if organic nitrogen inhibition occurs during the normal operating cycle, we can generally expect at least three times as long to desorb the nitrogen off the catalyst as it took to absorb the nitrogen onto the catalyst. More commentary is provided in the Answer Book.

DAVID VANNAUKER (Haldor Topsoe, Inc.)

The time to recover from a severe organic nitrogen event has a wide variation. It is dependent upon the feed type, feed endpoint, unit operating pressure, hydrocracking catalyst zeolite, hydrocracking catalyst zeolite content, and whether the hydrocracking catalyst is in first stage or second stage. The duration of severe organic nitrogen slip events has ranged from a few hours to several weeks.

JOE FLORES (Criterion Catalysts & Technologies / Zeolyst International)

Time required for hydrocracking beds to recover from nitrogen poisoning can vary from several hours to several days, weeks, or never, depending on the time and severity of the exposure and the type of catalyst in question.

In one example, due to a power outage, the second stage of a two-stage unit was exposed to untreated feed. For many hours, the second-stage catalyst was exposed to feed containing over 1500 ppmw (parts per million by weight) nitrogen, which resulted in complete deactivation of the second-stage catalyst system. Operation of the second-stage reactor at temperatures +10°F higher than normal for several days resulted in reversal of the deactivation, with the exception of the top bed which never fully recovered. The top bed catalyst essentially experienced permanent deactivation in this scenario.

Units that experience smaller nitrogen excursions for shorter periods can usually fully recover their activity, but the time to recovery can vary. It is typically not advised to operate the unit much above normal operating temperature at the time of exposure; because when the nitrogen desorbs off the catalyst, it can lead to instability and a temperature excursion. Careful attention must be paid to the unit while operating at elevated cracking temperatures so that when signs of recovery are evident, the bed inlet temperatures can be reduced to avoid an excursion.