Question 35: What experiences do the panelists have with naphtha hydrotreater combined feed exchanger fouling? How do you monitor fouling in this exchanger service?

Wayne Woodard (Valero Energy)

John Clower (Chevron)

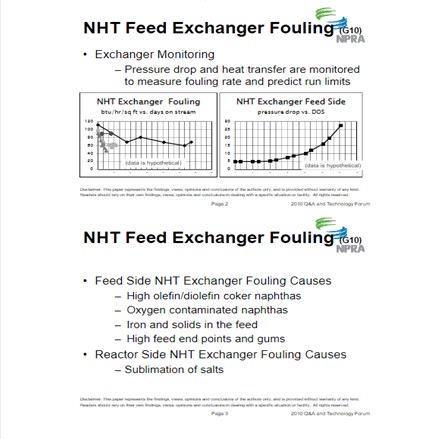

Feed side fouling of the NHT feed/effluent exchanger can be attributable to polymerization of olefins or diolefins. Storage of unsaturated materials from the Coker/FCC/Visbreaker may exacerbate the problem with the introduction of oxygen as a free radical that can promote polymerization.

Corrosion products also play a part in feed side fouling, though normally at the top of the reactor bed. Feed side fouling can be made worse by temperature cycling of the unit, causing more scale to break off from the metal surface through thermal expansion/contraction.

Effluent side fouling occurs in the form of salt de-sublimation in the cooler exchangers.

Chevron monitors the inlet and outlet temperature of each exchanger in the train via the DCS. Routine single gauge pressure surveys are also performed on these exchangers.

The NHT process engineer models fouling resistance using calculated heat transfer coefficients to trend performance of the combined feed exchangers over the catalyst cycle.

In the absence of rigorous temperature and performance modeling, normalized hot and cold side approach temperatures will provide indications of fouling at the exchangers, as will normalized fuel gas consumption at the fired heater.

Graduated metallurgies are often found in this exchanger service, with the hottest exchangers having stainless components and cooler exchangers with chrome molybdenum or carbon steel components. Fouling conditions may result in exceeding temperature limits of the cooler exchangers with respect to hydrogen attack. Feed side fouling can be mitigated with the following installations:

•Antioxidant injection, to limit polymerization to gum

•Anti-fouling injection, to disperse corrosion products

•Installation of a low temperature saturation reactor to remove diolefins and also uptake silica in the feed

•Reactor bed grading

Effluent side fouling is mitigated with a continuous or intermittent water wash, depending on the degree of fouling.

Gregg McAteer (Nalco Company)

Combined feed naphtha hydrotreaters that foul at a rate sufficient to affect charge rate in-between scheduled shutdowns are treated with antioxidants, antipolymerants, and or dispersants. We test the stream to see what combination of chemistry is required. We monitor the typical operating variables like pressure drop, temperature change, charge rate, etc. We also monitor the exchangers with our two-phase simulator to track actual vs. target performance.