Question 26: We are interested in minimizing our black oil production from the FCC by recycling heavy cycle oil and/or slurry to our FCC feed hydrotreater for aromatic saturation and further cracking. Do you have any experience with this operating mode or recommendations for reduced slurry make via optimization of an FCC pretreat unit?

JEFFREY MUELLER (Marathon Petroleum Company)

Recycle of LCO and HCO to FCCU units has been practiced within the MPC system for many years, both in field applications and laboratory pilot plant studies. In summary, the following hold true:

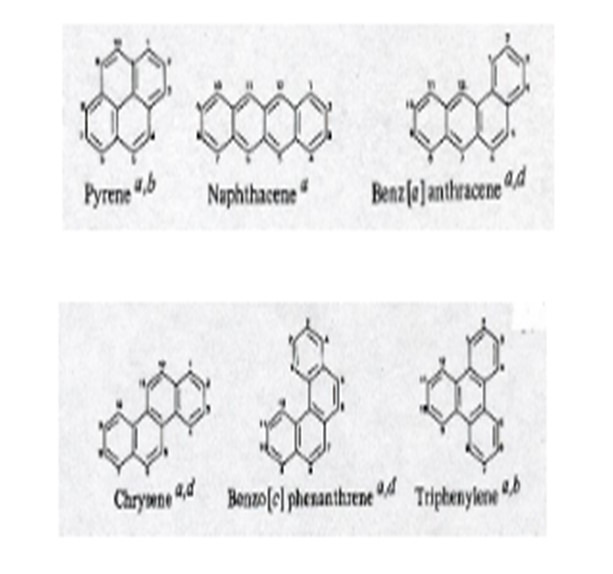

*HCO should never be recycled directly to an FCCU without being hydrotreated. In general, HCO contains a large amount of polynuclear aromatic components (hydrocarbons with multiple aromatic rings fused so that the rings share one or more sides). The geometry of these compounds makes them impossible to enter the zeolite cage of the FCCU catalyst, preventing them from being catalytically cracked. As a result, the only cracking mechanism is thermal, resulting in a large amount of coke and gas.

*Recycle through an FCC feed hydrotreater rearranges some of the polynuclear molecules into a form that can produce LCO or lighter products in the FCCU. In general, material that boils less than or equal to about 850°F can be converted into usable FCCU feed.

Limiting the discussion to HCO, if phenanthrene or anthracene are hydrotreated, one ring readily saturates and a second ring is relatively easy to saturate. A three-ring aromatic with one terminal ring saturated readily opens the saturated ring in an FCC riser, which makes a diesel boiling range diaromatic. If two rings are saturated, gasoline can be produced from this ring opening. As long as the molecule is linear (not Poly condensed), the saturated ring can enter the zeolite cage.

The situation becomes more complicated for a four-ring aromatic. Pyrene is a poly condensed molecule which is too bulky to enter the cage. However, one to two rings can be saturated in the hydrotreater, and the molecule at least has the potential to crack to distillate boiling range by sphere of influence or matrix cracking. Chrysene is a more or less linear four-ring aromatic, which should be readily crackable with one to two rings saturated, producing either gasoline or diesel products. On the other hand, five-ring aromatics begin to stretch the imagination, in terms of a mechanism to produce gasoline or diesel; and they readily condense to graphitic-type coke. A poly condensed five-ring aromatic (probably the lowest boiling) would have to both saturate and crack at least three rings to produce diesel: not a very likely occurrence. The more probable reaction would be saturation of one ring, which, even if it cracked, would still only produce slurry or HCO –at the cost of a significant amount of hydrogen. As a result, we concluded that the distillation of HCO for recycle should be terminated about in the region where five-ring aromatics begin to occur.

*Due to the above mentioned five-ring limit, slurry oil has a larger percentage of molecules that are typically not good candidates for recycle to an FCC feed hydrotreater. In addition, catalyst fines in slurry cause hydrotreater bed fouling. Typically, a more effective solution is to draw an HCO product and recycle this “portion” of the slurry.

*Typically, a refiner would not recycle HCO to your FCC feed hydrotreater if fresh gas oil was available. It is not going to upgrade into more valuable products, as well as gas oil.

*Even with HCO recycle, catalyst fines are a concern for hydrotreater bed fouling. Fines can be difficult to filter due to some being very small. An HCO stream should only be a candidate for recycle if it has little or no entrained fines.

A commercial test run was conducted at an MPC refinery during the late 1990s to measure the impact of recycling HCO through the FCC feed hydrotreater and FCCU. During the test run, 750 bpd HCO was recycled to the FCCU and the FCCU saw 300 bpd lower slurry yield and a reduction in coke make of approximately 7 wt%. However, the same refinery experienced an increase in FCC feed hydrotreater bed pressure drop that correlated with HCO recycle in the late 2000s that had been attributed to the carryover of catalyst fines to the hydrotreater bed.