Question 25: What is your philosophy for mitigating fouling and corrosion in reactor effluent cooler systems in hydrotreater or hydrocracker units during a short-term washwater pump failure scenario? How much time is allowed before initiating a unit shutdown?

ROBERTSON (AFPM)

We are going to finish with Question 25. Twenty-six was an Answer Book-only question anyway, and Robert and James have provided answers to 27 and 28 respectively in the Answer Book.

LEICHTY (Chevron USA, Inc.)

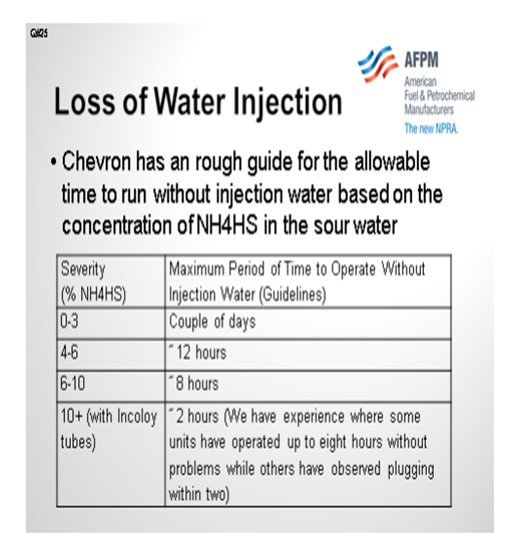

Chevron developed a rough set of internal guidelines that determine the allowable time to run without water injection. The guidelines are based upon ammonium bisulfide (NH4HS) concentration. For units that run at what we call low severity, which is zero to 3% NH4HS, we will allow a couple of days of operation without water injection. As the normal NH4HS concentration of the operating unit sour water increases, we allow progressively less time to run without water injection.

Once injection capability is restored, each bank of air cooler should be sequentially flushed with as much water as possible with all other banks receiving minimum water at all times. We use infrared scans to determine whether or not we still have tube plugging. You can shoot the fin fan banks from up above or from down below, depending on the configuration.

The NH4HS salts in plugged tubes can sometimes be re-sublimed by sequentially shutting off air cooler fans. The increase in bundle temperature can sometimes be enough to allow the ammonium bisulfide salts to vaporize. We have also used temporary solutions, such as hydroblast water pumps, as a mechanism to get water into the unit, but only if 25% liquid water can be maintained. Having less than 25% liquid water can be more damaging than having no water at all because of the potential for rapid hydrochloric acid corrosion.

PUI-NANG LIN (Flint Hills Resources, LP)

Is the table that you presented for the duration of the water outage based on corrosion rate or plugging of a certain percent of the tubes by salt? Does metallurgy of the tubes affect the result?

LEICHTY (Chevron USA, Inc.)

The duration of the water outage is based on plugging and the potential for subsequent corrosion.

STEPHEN PERRY (Motiva Enterprises)

I would propose to you that the Shell’s criteria are slightly different. I also encourage you to do a salt balance because when doing a salt balance, in less than eight hours, you can find out that you could start plugging off tubes that are not going to recover without your ability to get water in there. Companies will have different policies. Also, units salt up at different rates. So, I would definitely do a salt balance, understand your situation, and then make a decision based on all of the information.

LEICHTY (Chevron USA, Inc.)

That is how these tables were developed.

KEVIN PROOPS (Solomon Associates)

I have a follow-up question for Steve Leichty, and maybe for Steve Perry. Do you consider reducing feed rate or cutting out specific feeds when you lose washwater to reduce salt formation?

LEICHTY (Chevron USA, Inc.)

Absolutely. The first action is to shed higher nitrogen crudes and reduce the unit feed rate.

KEVIN PROOPS (Solomon Associates)

I would agree with also pulling the high nitrogen feedstocks out of the unit as a first step.