Question 25: Have you detected any hydrogen chloride slip in the stabilizer bottoms for any gasoline units (isomerization or reformer)? What are your Best Practices to prevent downstream unit corrosion?

DUNHAM (UOP)

Occasionally, isomerization units will slip some HCl or organic chlorides at the bottom of the stabilizer. The key here is having the proper reflux ratio on that tower because you need to keep the partial pressure of the HCl low enough that it will not overheat. So, you need a reflux-to-feed ratio of 0.5 to 0.8 to make sure that this chloride will not go down the stabilizer. We often see some refiners doing an energy audit. So, I will say, “Gee, we could save some energy if we cut the reflux ratio.” When they do the simulation, they see that it does not have the HCl. They do not understand that the HCl will go down the tower. I have seen this on a C4 isomerization unit. A customer sent a lot of chloride over to a sulfuric acid unit. The fractionator was wet, and the whole downstream overhead system was severely corroded. So, you really must be careful about stripping chloride out of the butane product.

PATEL (Valero Energy Corporation)

The HCl or organic chloride slip can occur in the isom stabilizer bottom. The reformer stabilizer operates at a relatively higher temperature, and the HCl should decompose at that condition. However, heavy organic chloride slip can occur from the reformer stabilizer bottom. Just maintaining a sufficient reflux-to-feed ratio for internal traffic in the isom stabilizer can push the HCl into the overhead where it belongs. The recommended reflux-to-feed ratio for the stabilizer is 0.5 to 0.8. However, at our unit, we operate at as low as a 0.25 reflux-to-feed ratio without experiencing any bottom slippage issues. In the reformer stabilizer, no chloride corrosion is expected if a facilitator is installed in front of stabilizer.

ABIGAIL SUP (Johnson Matthey Process Technologies)

Based on Johnson Matthey’s experience while working with various operators of catalytic reformers and isomerization units, ppm levels of chlorides have been detected in the stabilizer bottoms of both units. However, requests for chloride solutions for the stabilizer bottoms stream are more commonly received from catalytic reforming units. The typical chloride concentration reported by operators has been in the range of 3 to 5 ppmw. However, the number of chlorides present in each stream of a particular unit will vary based on operating parameters and unit design.

It is worth highlighting that organic chlorides can also be present and are more difficult to detect. If current testing has indicated that HCl is not detectable in the stabilizer bottoms but downstream corrosion is occurring, it may be that the chlorides are present, but in the form of organic chlorides. Johnson Matthey can coordinate testing, both field and lab, to measure both HCl and organic chloride levels across the unit. This sampling can help determine the number of chlorides present in various streams of a particular operating unit.

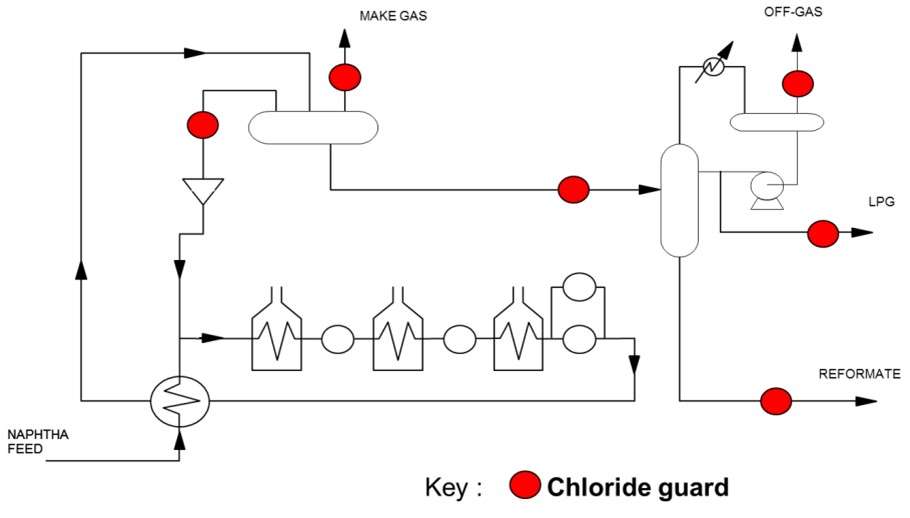

In order to prevent downstream corrosion caused by chlorides, chloride guards can be placed in various locations in the flowsheet. Chloride guard beds are an adsorbent and/or absorbent that can be installed to remove chlorides. Depending on the material employed, these beds can be designed to remove both HCl and organic chlorides down to less than 0.1 ppmw. The location(s) of the chloride guard bed(s) will depend on the operator’s issues and preferences. Below is a diagram showing possible locations of chloride guards in a typical catalytic reforming unit.

There are three chloride guard locations that will reduce the chlorides in the stabilizer bottoms stream. The most straight-forward choice would be to install a chloride guard directly on the stabilizer bottoms stream. An alternate option would be to install a chloride guard on the unstabilized reformate entering into the stabilizer column. The advantages of this option are that you also protect the stabilizer column itself from ammonium chloride fouling while at the same time removing chlorides from the other product streams exiting the column. This reduces the overall number of beds required if multiple product streams need to be treated. The size of the guard bed for the stabilizer column feed would also be similar to that used solely for the stabilizer bottoms. This means it would provide additional protection with little additional investment required. A third option to consider would be to install a chloride guard on the recycled hydrogen stream. This option would aid in reducing the chloride levels across the entire system, which would include reducing the chlorides exiting with the stabilizer bottoms.