Question 2: In hydrocrackers, how are your sampling systems designed to safely obtain inter-reactor / reactor effluent samples?

Martin Gonzalez (BP)

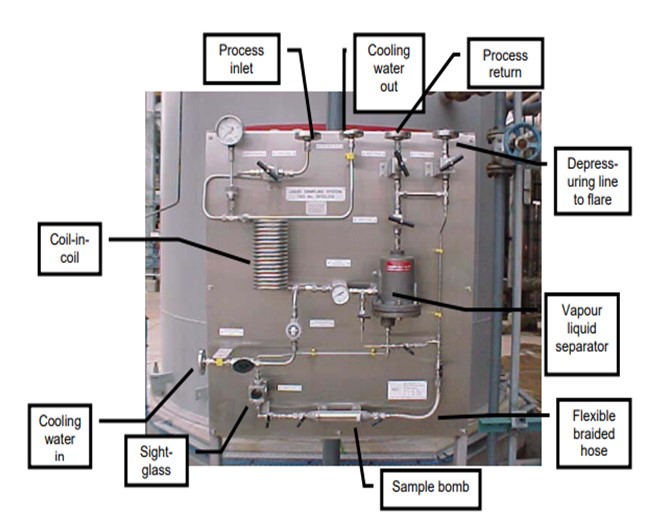

Inter-reactor sampling can be important for monitoring catalyst performance, troubleshooting, and measuring yields. In a hydrocracker, such a sampling system allows measurement of nitrogen slip from the pre-treat section into the hydrocracking stage. Several technology licensors offer designs for inter-reactor sampling. It is important for the system to be closed loop, venting to a safe low-pressure location such as a flare. Use of a sample pot with relief valve protection can allow use of closed sample bombs and quick-connects at lower pressure than the high-pressure reactor loop. It is useful for sample pots to have level gauges, pressure gauges, and temperature indication. Water-bucket-and-coil arrangements are typical for cooling the process stream. Be cautious of introducing permanent connections between utilities and process, such as when nitrogen is used for flushing, because this may lead to overpressure and intermixing. Valves used should be designed for repeated operation against high differential pressure. Reliability of root valves can be improved if procedures are sequenced to avoid opening and closing these valves against full differential pressure. A photo of an inter-reactor sampling system is shown here. Note that it may be desirable to have the sample container in a vertical orientation, rather than horizontal as in the photo. Please also refer to Safety question 1 of the 2008 Hydroprocessing Q&A Session, which addressed a similar issue.

Tim Lewer (Shell)

Taking inter-reactor or reactor effluent samples in a high-pressure hydroprocessing unit has many risk factors that need to be considered when designing the sample system. In many cases, plants have decided to remove or not use existing sample stations due to the risk. Where high pressure sample systems are used, there are a few common design considerations in addition to the previous discussion:

1. The sample system needs to be designed in such a way that the sample collection point and operator position while opening/closing the valves are sufficiently far apart to remove the operator from the line of fire if there were a release of high-pressure gas or H2S. This is often overlooked, but all high-pressure sample systems should be evaluated for this concern (i.e. recycle gas samples).

2. Clear operating procedures and specific operator training. The valve opening and closing procedure can even be posted as a fixed sign at the sample station to be read each time a sample is taken.