Question 16: What LCO 95% distillation point do you target for optimizing ULSD production? Do you see a significant catalyst life penalty with an increased LCO cut point?

Kaspar Vogt (Albemarle)

The purpose of adding more LCO is to improve the refinery’s financial performance by upgrading low value LCO to ULSD products.

The optimal 95% distillation point depends on operating conditions (H2 partial pressure and space velocity), unit objectives (cycle length / uplift) and product specifications. Adding heavier LCO can be limited by the specifications set on minimum cetane number/index, diesel density, PNA concentration and distillation. Adding heavier LCO will also introduce more sterically hindered dibenzothiophenes (very difficult sulfur species) and additional nitrogen compounds (inhibitors for HDS reactions) and 3-ring aromatics in the feed.

Using high activity catalysts such as STARSTM and NEBULA® can allow refiners to process heavier LCO, provided enough hydrogen is available. These catalysts have high hydrogenation activity to convert sterically hindered sulfur, uplift density and improve Cetane.

The availability of sufficient hydrogen is critical. Processing more LCO will require additional operating temperature and increase the exotherm in the catalyst beds due to the presence of more polyaromatics. Furthermore, the additional hydrogenation reactions will cause a corresponding increase in hydrogen consumption. This will reduce the operating window, increase the deactivation rate and set a shorter cycle length. If the cycle becomes uneconomic due to down time and turn around costs it can limit the operating strategy of processing more and heavier LCO.

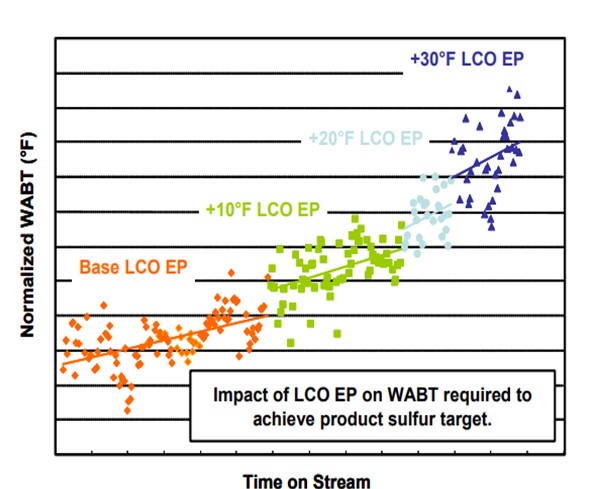

In cooperation with a US refinery, a commercial test was run where the LCO 95% and End Point (EP) were increased when the turnaround had been set and sufficient catalyst activity remained which the refinery chose to use up. The unit has a 1000 psig inlet pressure. The results of the test gave an interesting plot of required weight average bed temperature (WABT) vs. on stream time as the LCO became increasingly heavier.

In the figure above, we can clearly see that processing higher end point LCO requires additional operating temperature and increases the deactivation rate. We also see that end point increases of as little as 10 deg F can significantly increase both the required WABT, and the deactivation rate.

Martin Gonzalez (BP)

Difficulty in desulfurizing LCO relates directly to the concentration of hindered substituted dibenzothiophenes (DBT's). The optimal cut-point may be different for each hydrotreater depending on the individual capabilities of that unit (pressure, space velocity, and duty limits). Concentration of DBT's will also vary depending on degree of hydrotreating of FCC feed, and LCO total sulfur concentration may not be a good indicator. Our experience is that coke lay-down rates on catalyst will be greater as the concentration of polyaromatics increases. Thus, it becomes important to also consider LCO gravity, in addition to final boiling point and normal boiling point when considering deactivation rates.

Minh Dimas (CITGO)

We typically target LCO final boiling point instead of 95%. This is because with a constant 95% distillation point, the FBP can vary significantly – at least that is our experience. As the boiling point of LCO material increases, the difficulty to hydrotreat (as opposed to hydrocrack) grows exponentially. Because of this, there is an inherent hydrotreating catalyst life penalty with increased LCO distillation FBP. Of course, the degree of the penalty depends highly on a number of variables including but not limited to the total volume of catalyst, reactor temperature control / quench control, feed nitrogen concentration, feed sulfur concentration, and catalyst type. The unit design (system pressure, hydrogen purity, etc.) has a smaller effect.

Brian Watkins (ART)

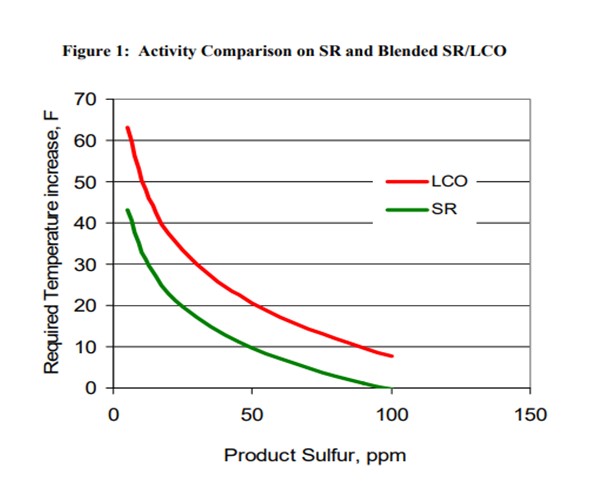

The addition of LCO to a ULSD hydrotreater has several effects such as increased hydrogen consumption, higher required reactor temperatures and possibly shorter cycle time. Figure 1 summarizes some of pilot plant data comparing a SR and a SR/LCO feed blend. It shows that the SR diesel requires a 43°F increase in temperature to go from 100 ppm sulfur down to 10 ppm sulfur. The 20% LCO blend requires almost 20°F higher temperature to achieve the same product sulfur relative to the SR feed. The product from the LCO blend also has a 2 to 3 number lower API compared to the SR product, and hydrogen consumption increases significantly for the LCO blend due to saturation of additional polyaromatic compounds found in the LCO. These latter consequences set limits on the amount of LCO which can be processed and still meet product cetane specifications and also hydrogen availability constraints.

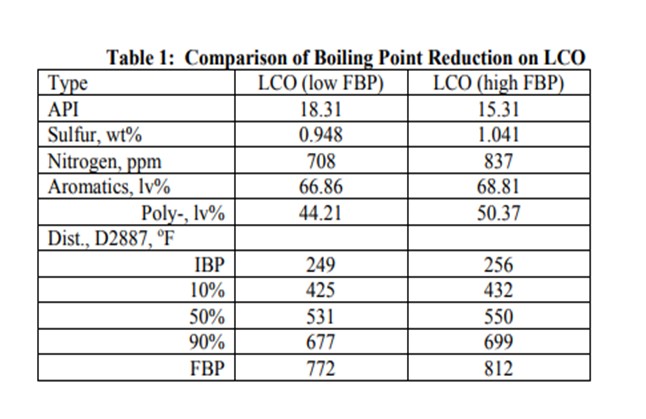

One option to re-gain some of the lost activity in adding additional LCO is to change the end point of the LCO in the feed. ART completed pilot plant testing on an LCO from the same FCC which had been cut at two different end points. Table 1 lists the analysis of the two LCO feeds and shows that the end points differed by about 40° F. The decrease in endpoint lowers the total sulfur by almost 1000 ppm and total nitrogen decreases by 129 ppm.

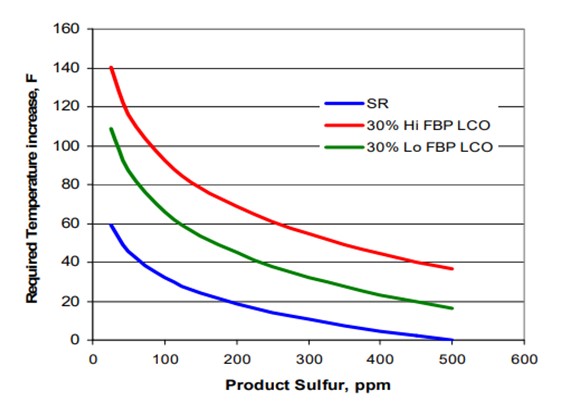

A comparison of activity on the two LCO feeds blended at 30% by volume into SR feed is shown in Figure 2. Over 30° F higher temperature is required to treat the higher endpoint feed to ULSD specification. This difference in activity corresponds to a significant decrease in the hydrotreater cycle length.

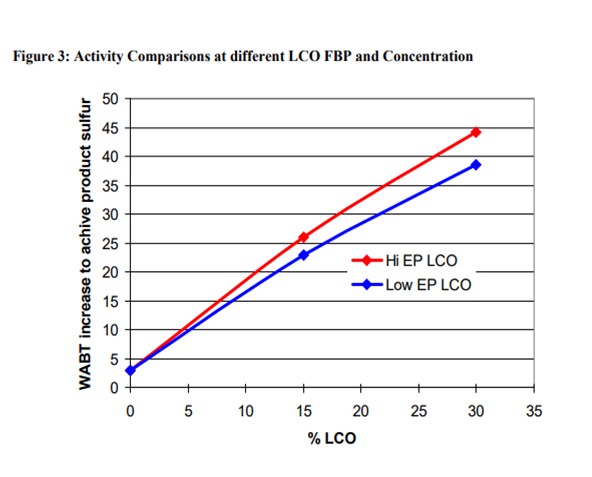

The addition of LCO has a major impact on activity for both the low and high endpoint LCO materials. The required temperature increase for ULSD in going from 0 to 30% LCO for the lower endpoint material is about 1.2° F per percent LCO. Processing the higher endpoint LCO increases the required temperature to about 1.4° F per percent LCO. Figure 3 demonstrates this more clearly in the form of a plot of the required temperature increase as a function of LCO content. Notice from the chart that the activity effects are not exactly linear with increasing LCO content. The first 15% LCO has a larger impact on activity than the next 15%.

Raj Patel (Haldor Topsoe, Inc.)

In the current market, a strong driver for many refiners to increase profitability is to increase the production of diesel; this can be done by increasing the end point of the LCO to the diesel hydrotreater to make more high value ULSD as compared to low value slurry oil.

It is clear that the higher the LCO cut point, the larger the ULSD product pool value. However, a great number of other considerations need to be addressed when increasing LCO cut point to the diesel hydrotreater with the primary concern being reduced catalyst cycle length.

Ideally there would be a single LCO 95% distillation point that all hydrotreating units should target to optimize the ULSD production, i.e., optimize the economics of the diesel hydrotreater. There is, however, no single LCO 95% distillation point that can be considered optimum for all hydrotreaters. Diesel hydrotreaters are designed for processing different feeds and different processing objectives. This results in units with different hydrogen partial pressures and LHSV. The limiting processing objective could be meeting ULSD sulfur, cetane number, cold flow properties, color product end point etc. All these constraints need to be considered individually, and it needs to be determined which will be the limiting constraint not only at SOR but also at EOR. Increasing LCO end point could possibly decrease attainable EOR temperature before the ULSD product goes off spec, effectively shortening the catalyst cycle length. Therefore, there is no single LCO 95% distillation point that can be considered optimum for all hydrotreaters. The ASTM D-86 distillation may hide a lot of the heavy end species, so it is recommended to use ASTM D-2887 distillation when looking at 95% boiling point.

Common for all hydrotreaters is, however, that hydrotreater catalyst life will be penalized with increased cut points. The reduction in catalyst life will come from increase in the required SOR WABT, increased deactivation rates and possibly reduced EOR temperatures:

Activity – Required SOR WABT

As a general rule of thumb for treating 100% LCO, it can be assumed that for every 2-4°F increase in LCO 95% boiling point, the required Weight Average Bed Temperature (WABT) of a hydrotreater must be increased by approximately 1°F to compensate for the increased feed sulfur and feed nitrogen levels. However, this impact is very pressure dependent. If the portion of LCO is smaller, it can be assumed that the required increase in WABT will be almost proportionally less.

If the cut point is lowered towards the end of the cycle, then the increase in required WABT will be regained due to lower severity feed (less sulfur, in particular the difficult sulfur species, and less nitrogen, which inhibits the hydrotreating reactions). If reducing end point for winter month operation, where cold flow properties are limiting, then the hydrotreater can be operated through the winter months with the lighter feed, even if the catalyst is at EOR in summer mode. However, the catalyst life lost from increased deactivation rate when processing the higher end point LCO will not be regained.

Catalyst deactivation

The other effect to consider when raising LCO end point is catalyst deactivation rate. This effect will be dependent on the increase in Tri+ aromatics and nitrogen content of the LCO. As a general rule of thumb the deactivation rate may increase by up to 10% for every 10°F increase in LCO EP. Based on the above it is clear that increasing LCO cut point will negatively impact catalyst life from a standpoint of catalyst activity as well as stability. Increasing LCO cut point (or other heavy portions of the feed in general) must ALSO be managed to meet properties other than sulfur, including cold flow properties, color, cetane number, distillation spec and gravity. Several of these specifications may lead to a lower attainable temperature at EOR due to equilibrium constraints.

The use of the various feed stocks available to the refiner (including LCO) to a diesel hydrotreater is ideally optimized through not only the use of proven kinetic models but also must include refinery LP models. This will provide detailed predictions on the costs and benefits of increasing the cut point of the available feed stocks.

Topsoe has designed diesel hydrotreaters processing LCO including multiple units processing 100% LCO.