Question 12: Are you designing or revamping isomerization units’ radial reactor temperature indicators?

SABITOV (Phillips 66)

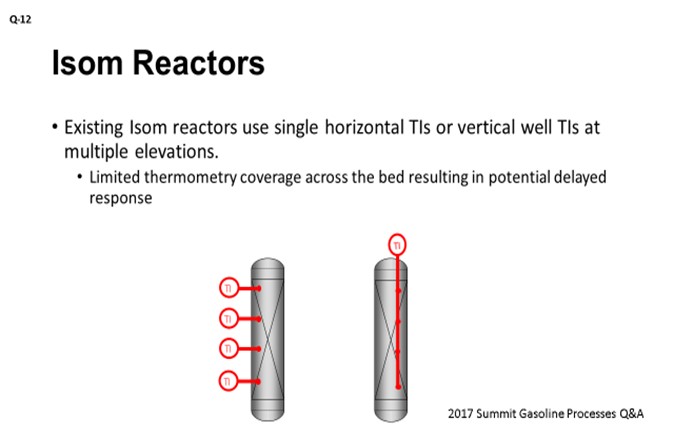

Phillips 66 operates several vintages of isom (isomerization) units, including revamped units. Therefore, we have various reactor thermometry designs mainly consisting of single horizontal TIs at multiple elevations or several elevation TIs within a vertical thermal well. We feel that temperature measurement at a single point for the given bed elevation provides limited thermometry coverage across the bed, resulting in potential delayed response in events of reactor temperature runaway. This topic is being actively discussed within our company as part of the new isom emergency shutdown standard.

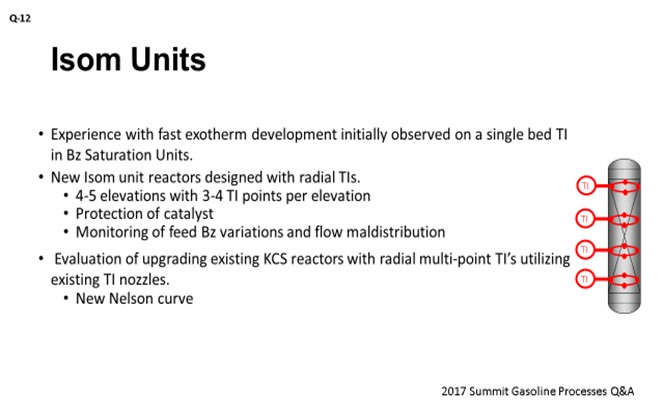

We arrived at our current thinking after reviewing several temperature runaway incidents in the benzene saturation (BenSat) units (equipped with multi-point TIs) where fast exotherm development was initially observed on a single-bed TIs while other TIs – at similar bed elevation on the other side of the bed – were appreciably slower to respond. Such behavior can probably be explained by flow distribution problems.

We are currently designing a grassroots isom unit with several radial TIs at each elevation. This improvement should help to protect catalyst from high temperature exposure by timely activating relevant emergency shut down systems including reactor depressuring as well as closely monitor bed exotherm due to feed Bz (benzene) variations and/or potential flow maldistribution during transient operating conditions.

We are also in the process of evaluating upgrading remaining killed carbon steel isom reactors with radial multi-point TIs utilizing existing TI nozzles. There have been revisions of the Nelson curve which might put some of the killed carbon steel BenSat and isom reactors under tighter temperature constraints and require better thermometry coverage.

DOUG BECCI (Honeywell UOP)

Honeywell UOP does not typically design Penex™ or Butamer™ units with radial temperature indicators in the reactors. UOP standard design is to have a single thermocouple at regular intervals in the catalyst bed. We typically show these TIs in a straight line down one side of the reactor. Note that we have added radial TIs where the customer has specifically requested them for a new unit and that it would be possible to add them during a revamp if the original reactor had an existing radial TI design. Multi-point thermocouples supplied by Gayesco and DailyThermetrics have been used.