Question 100: What conditions or contaminants will deactivate ZSM-5 additive? What is the half-life of ZSM-5 in clean feed operation? Will contaminants such as vanadium, sodium or other metals adversely affect the propylene selectivity of ZSM-5? What is the best way to monitor the effectiveness of the ZSM-5?

Ray Fletcher (Intercat)

The deactivation mechanism for FCC catalyst is primarily related to unit cell size reduction, and eventually, collapse or sintering of the zeolite crystal. The mechanism of ZSM-5 deactivation is quite different. The deactivation mechanism is simply the dealumination of the ZSM-5 crystal and activity is lost through the loss of active aluminum sites. The crystal structure does not collapse. The activity retention and half-life of the ZSM-5 additive in the circulating inventory is strongly affected by hydrothermal conditions within the regenerator with temperature being the dominant variable.

ZSM-5 additive activity is less affected by contaminant metals than FCC catalyst. This is due to the fact that heavy feed molecules containing contaminant metals such as vanadium are less likely to crack on ZSM-5. ZSM-5 will therefore maintain its activity longer than FCC catalyst. It is worth pointing out that a unit experiencing high equilibrium vanadium levels will likely experience a loss in conversion which reduces LPG yields. This may give the appearance of a ZSM-5 effect. The propylene selectivity will likely remain unaffected.

The activity retention difference between ZSM-5 and FCC catalyst will increase as the equilibrium metals level increases. Intercat has evaluated ZSM-5 additive half-lives for several units and has found a typical half-life of approximately 18 days with a minimum of two days and a maximum of 36 days. ZSM-5 additive activity in an operating unit is strongly affected by the catalyst replacement rate. Units having a very high replacement rate present a higher average ZSM-5 activity then units with very low change out rate.

A paper presented at the 2000 ACS conference investigated the subject of LPG selectivity differences in detail. This study reviewed additives having different ZSM-5 crystal content, different levels of additive additions in the FCC, additives from different manufacturers, additives with different silica-to-alumina ratios and additives steamed at different severities. The results of the study can be plotted on one chart (include chart).

This data demonstrates that if one additive were more selective than another the propylene yield would fall on a different line which did not occur. All additives tested at all concentrations fall on the same line. We also see that the propylene yield increases faster than butylene yield and that higher delta LPG yield leads to higher propylene yields. Additive zeolite content, type, method of manufacture, and steaming severity has no effect on the selectivity of the final LPG product. The ratio of propylene to butylene in the final product depends only on how much LPG is made. The conclusion is that ZSM-5 additive selectivity is determined by the zeolite structure alone. Therefore, measuring activity differences is more important than looking for selectivity differences with standard ZSM-5 additive. (Please note that these results apply only to standard ZSM-5 technology.)

While propylene selectivity's are determined by the ZSM-5 crystal structure, the activity and stability of the various additives are determined by the crystal stabilization technology employed plus the interaction of the crystal with the matrix. An additive containing properly stabilized ZSM-5 crystal combined with a strong matrix will result in excellent activity retention with superior propylene yields when compared to other technologies. Intercat, and other suppliers, has invested significantly in the development of ZSM-5 additive technology. This is reflected in our broad product portfolio. Intercat possesses a broad range of ZSM-5 additives maximizing propylene, butylene and octanes. Additionally, Intercat produces ZSM-5 additives which minimize LPG increase for wet gas compressor limited operations.

There are several selectivity-based ratios which can be used in monitoring ZSM-5 performance.

These include: propane olefinicity, propylene yield vs. LPG, propylene vs. conversion, propylene vs. butylene and propylene vs. gasoline. The most important of these ratios are the propane olefinicity and the propylene-to-LPG ratio.

Matthew Meyers (Western Refining)

In VGO operation with less than 0.5 ppm vanadium, the half-life was observed to be roughly 18 days. For use in an LP model or to ensure that the alkylation unit remains optimized at varying feed rates, monitor the C3= and C4= yield shifts relative to FCC feed rate. A typical vector during z additive usage might be +3 for C3= vol% of feed and +2 for C4= vol% of feed, depending on the z additive dosage rate.

Kristen Wagner (Grace Davison Refining Technologies)

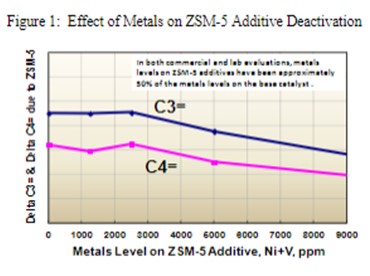

ZSM-5 based additives maintain their activity in high metals applications because they deactivate at a much lower rate than their Y-zeolite base catalyst counterparts. Grace has extensive R&D and commercial experience with ZSM-5 containing additives used in FCC units, including those that are designed for maximum propylene yield. These commercial FCC operations vary in feed metals levels, feed type, unit design and operating conditions. When analyzing commercial Ecat for ZSM-5 additive performance, it has been observed that feed metals will preferentially adhere to the base catalyst versus the ZSM-5 additive. Separation of equilibrium catalyst into its base catalyst and ZSM-5 additive components shows the ZSM-5 additive typically only contains about half the metals of the FCC base catalyst. In laboratory deactivation studies by Grace, ZSM-5 additives begin to deactivate at Ni+V loadings of 3000 ppm and greater, as seen in Figure 1 below. However, based on our current commercial experience, a ZSM-5 additive sample containing 3000 ppm Ni+V, would likely require approximately 6000 ppm Ni+V on the circulating base catalyst.

ZSM-5 additives are very stable and maintain activity much longer than other FCC catalysts or additives. The specific half-life of a ZSM-5 additive will vary from unit to unit but could easily range from two weeks to significantly longer, depending on the FCC operation. In Grace’s experience, the half-life of a ZSM-5 additive strongly depends on the operating conditions of the unit and not as much on the feed type or metals levels. Variables which will impact the half-life of a ZSM-5 additive include, regenerator temperature, unit pressure, and circulation rate, which influences the number of cracking cycles the additive undergoes in the unit each day. We have commercially observed higher than typical ZSM-5 deactivation rates in units running clean feeds but operating at higher pressure, higher circulation rates and higher regenerator temperatures.

ZSM-5 based additives are more resistant to sodium and potassium promoted zeolite destruction than Y-zeolite. Vanadium will likely have the greatest effect on ZSM-5 deactivation, however all contaminants in the FCC will have a much stronger effect on base catalyst deactivation, before they will adversely impact the ZSM-5 activity. Grace has not experienced any shifts in propylene selectivity due to contaminant levels or deactivation of ZSM-5 however more research is needed on this subject to provide a definitive answer.

For evaluating the effectiveness of ZSM-5 additives in a commercial unit, a common approach is to monitor propylene and butylene yields as a function of corrected conversion. ZSM-5 additives will increase LPG olefins for each given level of conversion. Another recommended method to measure the effectiveness of ZSM-5 additives is to analyze the increase in gasoline octane by evaluating gasoline octane as a function of reactor outlet temperature.

Grace has also been successful in evaluating ZSM-5 based additive performance using a multivariable regression approach. By utilizing a statistical tool such as Minitab, the LPG olefin or gasoline octane shifts can be quantified as a function of feed properties, operating conditions and ZSM-5 concentration.

Laboratory options also exist for measuring ZSM-5 additive effectiveness in the unit. In a controlled laboratory setting, performance comparisons can be made by taking a ZSM-5 containing equilibrium catalyst sample and a non-ZSM-5 containing equilibrium catalyst sample and analyzing them in an ACE unit or riser pilot plant, using a constant feedstock. This method is beneficial for analyzing ZSM-5 performance in commercial units that have experienced large changes in feed or operating conditions, which make ZSM-5 additive performance evaluations more challenging.

In summary, ZSM-5 based additives have excellent activity and stability even in high metals applications. Grace ZSM-5 additives have been shown to perform well with all types of FCC catalysts and FCC feedstocks and under a wide range of operating conditions and unit designs. Grace manufactured ZSM-5 additives are currently in use in over 70 FCC units worldwide and in more than half of the FCC propylene maximization operations in EMEA and Asia.