Question 1: How do you manage organic fluoride compounds in effluent and recycle streams in an HF alkylation unit? How do you detect upsets, and how are the impacts on downstream units mitigated?

SHARON (Valero)

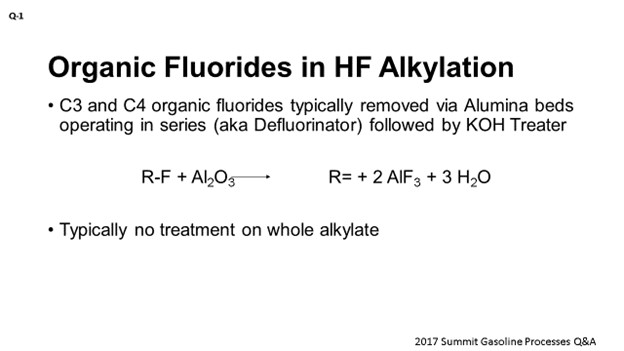

Combined fluorides are formed by the addition of HF (hydrogen fluoride) to an olefin. Generally, when you see high organic fluorides in your C3 and C4 streams, it is generally caused by one of the following: low operating reactor temperatures, low acid strengths, low I/O (isobutane/olefin) ratios, or low acid-to-hydrocarbon ratios. C3 and C4 organic fluorides are typically removed via alumina beds. The feed to the defluorinators – that is, the alumina bed – is heated to about 400 to 450°F. Typically, you target about 450°F. The reaction is shown in the following equation:

Usually, the alumina will pick about 20 to 25% by weight. The stream is cooled and then treated in KOH (potassium hydroxide) to remove any existing free HF or post-treat. Safety-wise, upsets in the defluorinators are generally caused by free HF. Therefore, you should have midpoint and outlet TIs (temperature indicators) to help detect any large exotherms.

SUGG (Honeywell UOP)

Kyle, good response. From our perspective, very little has changed on this subject since this question was originally posed in 1979. Internal recycle streams were typically not monitored for organic fluoride compounds because they are converted back to HF as they go through the reactor section. We do know one refiner who monitors fluoride compounds in every cycle, but it is not clear to us how the information is used. It is very atypical to monitor.

The alkylate product is typically not defluorinated. Upsets are generally detected by changes in other process variables such as acid purity. However, upsets do go undetected in some units. Reliable online analyzers for organic fluorides are not available. Best Practice is to minimize these undesirable fluoride compounds in the products to maintain a reactor temperature above 80°F, maintain HF purity above 87%, and maintain proper mixing of the feed into the reactors.

ROBERTSON (AFPM)

Those are the responses from the panel. Any questions or comments from the audience? You can also see the results of the poll for this Question on the app. It looks like 92% said no; 8% said yes. Does anyone want to see that on the boards? This is a simple one. It just now changed to 93% to 7%, so 13 out of 14 respondents said no. Maybe somebody hit yes by accident? [Laughter] The result is 93% to 7%.

Results to Poll for Question 1: No = 93%; Yes = 7%

RICHARD TODD (Norton Engineering Consultants, Inc.)

Typically, organic fluorides are managed in the butane and propane effluent streams from an HF alkylation unit. Treatment of the isobutane recycle stream is not needed. The propane and butane products are typically treated in alumina treaters to remove the organic fluorides and then in KOH treaters to remove moisture (which is created in the alumina treaters) and any HF “slip”. The alumina and KOH treaters are each equipped with multiple vessels and arranged in a lead/lag type of system so that the treaters can have the alumina or KOH (potassium hydroxide) replaced with the alkylation unit in service.

Proper monitoring of the organic fluoride content in between the two alumina treaters, as well as the moisture and HF in between the two KOH treaters, is essential to ensuring that the propane and butane products remain free of contaminants that may impact downstream process units. The feed organic fluoride content can also be monitored and tracked, and the “remaining life” in the alumina and KOH treaters predicted, to better schedule changeouts of the alumina and KOH.

Butane alumina and KOH treaters may pose some unique challenges with corrosion as the high organic fluorides in the untreated butane results in high moisture that may become extremely corrosive with any HF slip. Piping and equipment between the alumina and KOH treaters may need to have upgraded metallurgy to manage this corrosion risk.